At NBNQC, we pride ourselves on being a renowned provider of quality inspection services, particularly focusing on valve quality control and inspection in China. Our mission is to cater to the needs of global customers seeking high-quality valve products from Chinese manufacturers. With our extensive industry experience and commitment to excellence, we ensure that the valves our clients source meet their requirements and international standards.

Contents

Our Expertise and Team

NBNQC boasts a team of experienced engineers and technical experts who possess a wealth of industry knowledge and expertise. Our professionals are dedicated to upholding the highest standards of quality control, bringing meticulous attention to detail and a proactive approach to every project. This ensures that our clients receive valve products that are reliable, durable, and compliant with their specifications.

Comprehensive Range of Services

We offer a wide array of services designed to cover every aspect of valve quality control and inspection. Our comprehensive approach ensures that all potential quality issues are identified and addressed promptly. Here are the key services we provide:

1. Manufacturing Process Monitoring

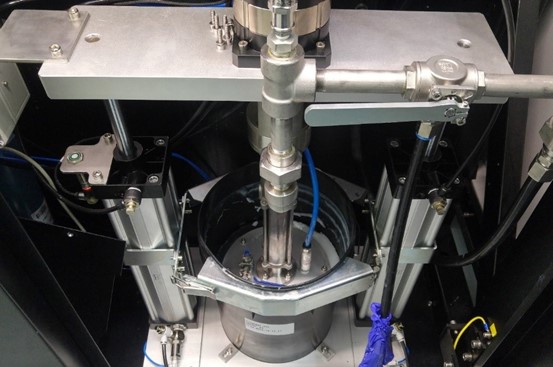

Our manufacturing process monitoring service involves close oversight of the entire valve production process. We ensure that every step adheres to the required specifications and quality standards. This includes:

- Raw Material Inspection: We examine the raw materials used in valve manufacturing to ensure they meet the necessary quality standards. This prevents defects and ensures the integrity of the final product.

- Process Control: Our team monitors the production process to maintain consistency and quality. We check for adherence to specified procedures and guidelines.

- Equipment Calibration: We verify that all manufacturing equipment is properly calibrated and functioning correctly to produce valves that meet the desired specifications.

- Product Aesthetics Evaluation: We assess the visual aspects of the valves, ensuring they meet aesthetic standards and do not have any surface defects.

2. Sampling Inspection

Sampling inspection is a critical component of our quality control process. We select samples from production batches and subject them to rigorous testing. This includes:

- Physical Testing: We perform detailed examinations of the valves’ physical attributes, such as dimensions, weight, and material properties.

- Functional Testing: We assess the operational performance of the valves, ensuring they function as intended under various conditions.

- Reliability Assessment: Through these tests, we determine the reliability and durability of the valves, providing our clients with confidence in their products’ performance.

3. Testing and Validation

To ensure that the valves meet relevant standards and specification requirements, we conduct a variety of tests and validations. These tests include:

- Pressure Testing: We test the valves under high-pressure conditions to verify their ability to withstand operational pressures without leaking or failing.

- Leak Testing: We check for any leaks that could compromise the valve’s performance and safety.

- Seal Performance Testing: We evaluate the effectiveness of the valve seals, ensuring they prevent any unintended flow or leakage.

4. Document Review

Our document review service involves a meticulous examination of all valve-related documents and certificates. This ensures compliance with regulations and contractual requirements. We review:

- Quality Records: We scrutinize records to verify that all quality control processes have been followed correctly.

- Test Reports: We examine test reports to ensure that all necessary tests have been conducted and the results meet the required standards.

- Compliance Certificates: We verify the validity of compliance certificates, ensuring the valves meet all relevant industry regulations.

5. Pre-shipment Inspection

Before the valves are shipped to our clients, we conduct a final comprehensive inspection. This pre-shipment inspection ensures that:

- All Quality Expectations are Met: We verify that the valves conform to our clients’ quality standards and specifications.

- Packaging and Labeling: We check that the valves are packaged and labeled correctly to prevent damage during transportation and ensure easy identification.

Commitment to Excellence

At NBNQC, our aim is to provide clients with independent and objective quality inspection services. We are dedicated to assisting our clients in ensuring the quality and performance of their valve products. Our extensive expertise and unwavering commitment to excellence make us a trusted partner in China for valve quality control and inspection.

Why Choose NBNQC?

Choosing NBNQC means partnering with a team that understands the critical importance of quality in valve manufacturing. Here are some reasons why we are the preferred choice for many global clients:

- Independent and Objective: We provide unbiased inspection services, ensuring that our assessments are fair and accurate.

- Industry Expertise: Our team has extensive experience in the valve industry, allowing us to provide insightful and effective quality control solutions.

- Comprehensive Services: We offer a full range of inspection services, covering every aspect of valve quality control.

- Client-Centric Approach: We prioritize our clients’ needs and work closely with them to meet their specific requirements.

- Commitment to Quality: We are dedicated to maintaining the highest standards of quality in everything we do.

Contact Us

For further information on our services or to discuss your specific requirements, please feel free to contact us. We are eager to serve you and meet your quality control and inspection needs for valves in China. Partner with NBNQC for reliable, high-quality valve inspection services and ensure the success of your projects with confidence.