Bags & Fashion accessories quality control services in China

As a leading third-party inspection company based in China, we specialize in providing comprehensive quality control services for the bags and fashion industry. Our expert team has a deep understanding of the unique needs and challenges of fashion products, offering a range of thorough inspection services including material checks, design verification, dimensional accuracy, craftsmanship quality, and packaging integrity.

Utilizing state-of-the-art technologies and methodologies, we ensure that each product not only meets international standards but also satisfies specific market and customer requirements. We are committed to helping your brand maintain exceptional quality, enhance market competitiveness, and deliver an unparalleled product experience to your consumers.

The key points of Bags & Fashion Accessories inspection

This includes a meticulous examination of material quality, ensuring fabrics, leathers, and other materials meet durability and safety standards. The inspection process also rigorously evaluates the construction and craftsmanship, scrutinizing stitching, seams, and fastenings for structural integrity. Color fastness and consistency are checked to guarantee the product's aesthetic appeal remains intact over time.

Additionally, the inspection includes verifying dimensions and design accuracy against client specifications, and conducting functionality tests for zippers, clasps, and other hardware. Packaging and labeling are also examined for compliance with legal and brand standards.

Appearance and style

When conducting third-party inspections of bags and fashion products, verifying the style and color of the finished products typically involves two main steps. Firstly, inspectors utilize approved samples or detailed specifications provided by the client for sample comparison and visual inspection. They carefully compare the appearance, color, style, and other key design features of the finished products to ensure they fully meet the client's requirements and standards.

Additionally, to ensure the accuracy and consistency of the color, the method of Pantone card comparison is usually adopted, and inspections may be conducted under different lighting conditions.

Material

The verification of materials used in products typically involves confirming the type, quality, and source of the materials. Inspectors, based on the material specifications provided by the client or a confirmation sample, carry out visual and tactile inspections to verify that the correct materials (such as leather, fabric, metal, etc.) are used in the product. Additionally, they may examine chemical test reports of the materials or use specific instruments to verify the composition and quality of the materials.

Furthermore, inspectors conduct durability and performance tests to ensure the materials meet the product's usage requirements. This may include tests for wear resistance, tear resistance, and colorfastness of the materials. For bags, this could involve testing the durability of zippers and the strength of fasteners. For fashion products, tests might be conducted on the wrinkle resistance of fabrics and the dimensional stability after washing.

Workmanship

Sampling

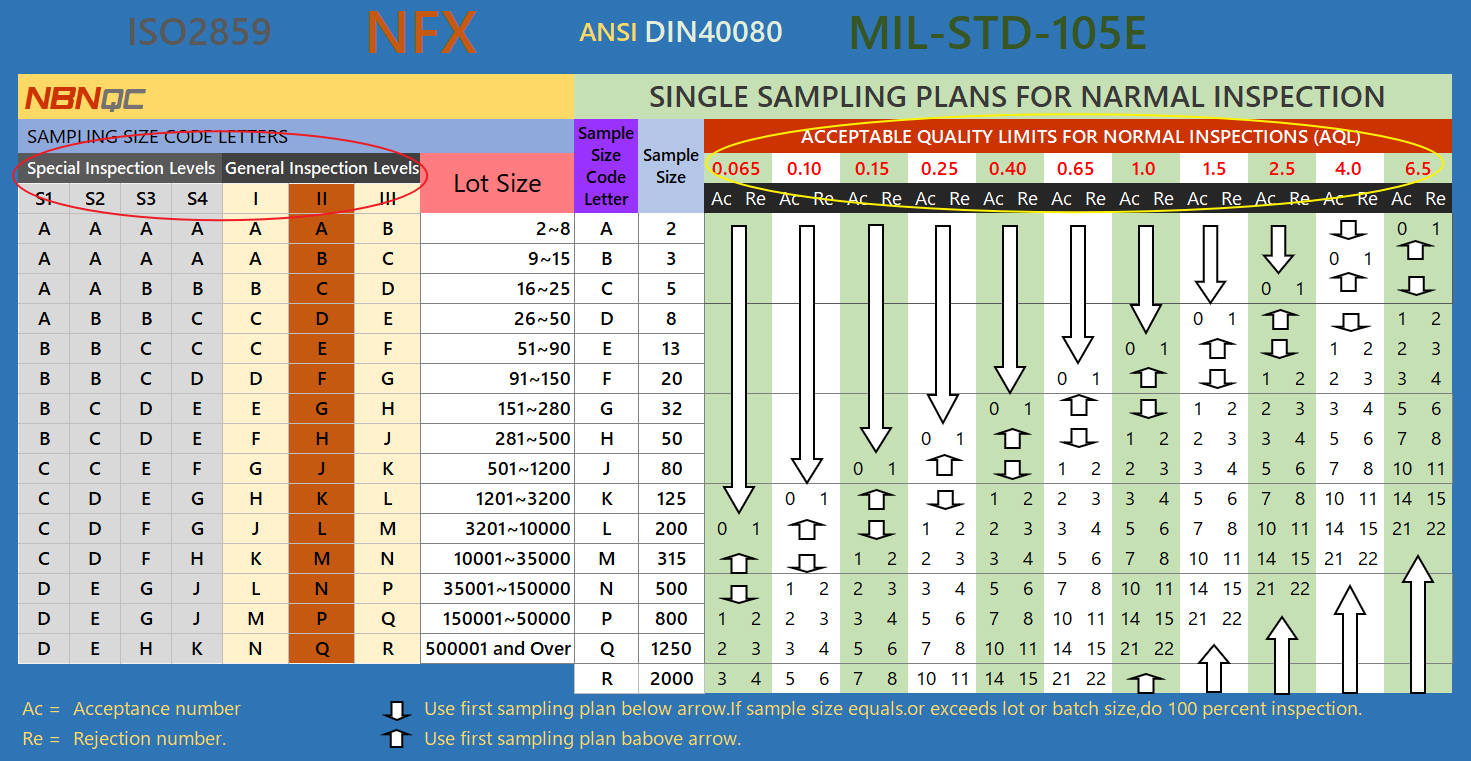

The number of samples for random inspection is determined based on the INSPECTION LEVELS requested by the client and the LOT SIZE of the goods. Then, find the corresponding AQL on the table. For example, if the required INSPECTION LEVEL is II, AQL is 0/2.5/4.0, and the LOT SIZE is 5000 pcs, then 200 pcs will be randomly sampled. The acceptable range for the number of defects is Critical 0 pcs/Major 10 pcs/ Minor 14 pcs. If the number of defects exceeds these limits, the goods will be rejected.

(Default: Inspection level II, AQL 0/2.5/4.0)

Quality check

Each sample selected for random inspection is individually examined, and all defective products are identified and segregated. These defective products are then categorized and quantified. This result determines whether the entire batch of goods falls within the AQL (Acceptance Quality Limit) range and is the key basis for deciding whether to accept or reject the shipment.

Classification of defects in bags & fashion accessories

Critical

Discover scissors or needles, mold, insects or insect eggs, as well as other items that pose a threat to user safety, environmental safety, or do not comply with legal regulations.

Major

Fabric color variation, noticeable misalignment or twist, holes, fabric or accessory damage, and other appearance defects affecting sales.

Minor

Untrimmed thread, small spots or stains, or other defects inconspicuously that have less effect on appearance.

Size Measurement

Appropriate measuring tools such as tape measures, or electronic measuring instruments are used to measure various parts of the product, ensuring that its dimensions comply with the specifications and standards provided by the client. Inspectors meticulously measure the length, width, height, and other key dimensions of the product (like the length of straps, size of pockets, etc.), and cross-reference these measurements with design drawings or samples to ensure the accuracy and consistency of the product's dimensions.

Label & Logo

A detailed visual inspection is conducted on the position, size, color, and design of the labels and logos. Inspectors compare these against the specific standards or samples provided by the client to ensure that the placement of labels and logos is accurate and their size and design meet the specification requirements.

As well as check the print quality of the labels and logos, including the accuracy and clarity of colors, and look for any printing errors or blurriness. For specific safety or compliance marks, such as washing labels or certification logos, additional compliance checks are carried out to ensure all information is accurate and adheres to relevant regulatory requirements.

Packing & Packaging

The quality and durability of packing and packaging materials are thoroughly examined to ensure they are robust enough to protect the products during transit. Inspectors check the accuracy and integrity of the packaging design, including print quality, labels, logos, and any brand-related graphics. Additionally, the inspection encompasses the verification of packaging dimensions, weight, and stacking methods to meet transportation and storage requirements, as well as assessing the use of environmentally friendly standards and recyclable materials to ensure the packaging meets sustainability and compliance standards.

Common Tests of Bags & Fashion Accessories Inspection

-

Carton assortment check

-

Carton drop test

-

Function test

-

Loading test

-

Color fastness test

-

Color shading check

-

Adhesive test

-

Smell check

-

Barcode scan test

-

Fitting test

-

Metal detection test

-

Stuffing material check

-

Waterproof test

-

Fabric weight test

-

Fatigue test

-

Wear test

-

Pull test

-

Symmetry check

-

Bend or flex test