Contents

- 1 Instruction

- 2 Detailing Inspection Requirements: The Foundation of Efficiency

- 3 Synchronization with Suppliers: Timing is Key

- 4 Standardizing Inspection Reports: Clarity Leads to Action

- 5 Cost Allocation in Re-Inspections: A Fair Approach

- 6 Selecting a Third-Party Inspection Company: Balancing Cost and Expertise

- 7 Case Study: A Model Approach

- 8 Conclusion

Instruction

In an era where global trade hinges on efficiency and quality, the role of third-party inspections in China’s vast supply chain network is increasingly critical. Businesses worldwide depend on these inspections to ensure product standards, yet often grapple with the associated costs. This detailed exploration addresses strategies for optimizing third-party inspections, focusing on precise requirement communication, effective inspection scheduling with suppliers, standardized reporting, strategic cost allocation for re-inspections, and selecting an adept inspection service provider.

Detailing Inspection Requirements: The Foundation of Efficiency

Effective third-party inspections begin with unambiguous communication. Businesses must articulate their expectations to the inspection companies to avoid costly misunderstandings. This involves:

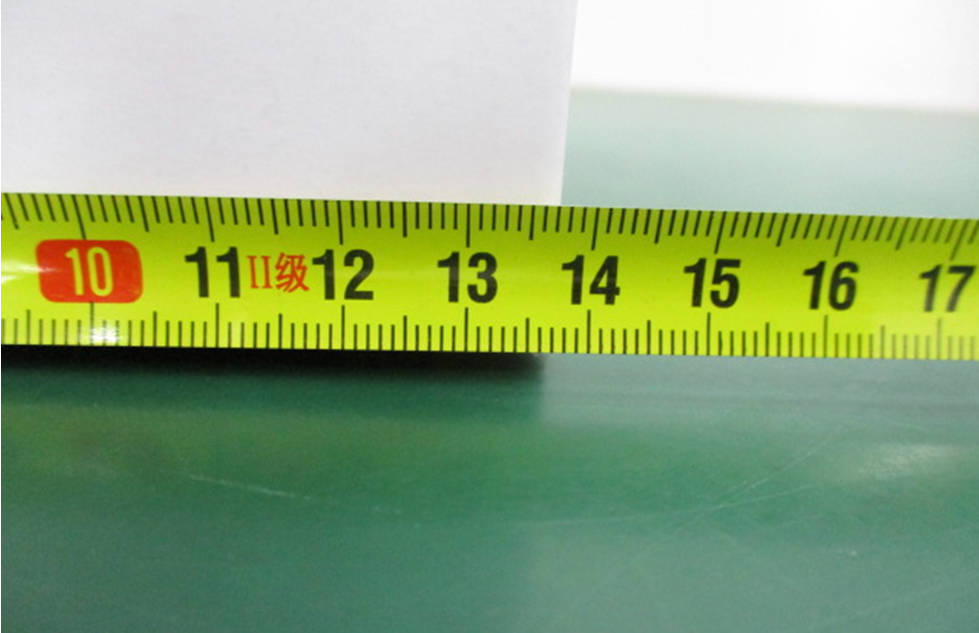

- Outlining specific product specifications, including materials, dimensions, and functional criteria.

- Detailing inspection methodologies, focusing on critical quality checkpoints.

- Establishing clear quality thresholds, defining acceptable and unacceptable variances.

- Highlighting any special requirements, including environmental and safety standards.

Synchronization with Suppliers: Timing is Key

Coordinating inspections with suppliers ensures that products are ready and compliant, minimizing delays and redundant checks. This requires:

- Advanced scheduling with suppliers to align production timelines with inspection windows.

- Regular communication updates to adjust for any changes in production schedules.

- Implementing a system for suppliers to confirm readiness, reducing the likelihood of inspection cancellations or delays.

Standardizing Inspection Reports: Clarity Leads to Action

A standardized inspection report format is essential for clarity and actionable insights. These reports should encompass:

- Comprehensive documentation of the inspection process, including date, time, and location.

- Detailed descriptions of the products inspected, correlating with the provided specifications.

- A thorough account of inspection findings, categorizing defects or non-conformities.

- Insightful recommendations and next steps based on the inspection outcomes.

Cost Allocation in Re-Inspections: A Fair Approach

To encourage quality production from the outset, it’s essential to have a clear agreement on re-inspection costs. This involves:

- Drafting contractual terms that stipulate the supplier’s responsibility for costs incurred due to failed inspections.

- Setting up a transparent process for re-inspection, ensuring all parties are aware of the implications of non-compliance.

- Encouraging suppliers to invest in their quality control measures to avoid the need for repeated inspections.

Selecting a Third-Party Inspection Company: Balancing Cost and Expertise

- Choosing the right inspection company is pivotal. The selection process should consider:

- The company’s credentials, including industry certifications and accreditations.

- The expertise and track record of the inspection team.

- Cost structures compared to the scope and depth of services offered.

- Client testimonials and industry reputation to gauge reliability and service quality.

- The company’s technological capabilities for conducting inspections and reporting.

Case Study: A Model Approach

For instance, a leading electronics manufacturer partnered with a renowned inspection company, leveraging their expertise in advanced product testing. By integrating the supplier’s production schedule with the inspection timeline, they reduced inspection-related delays by 30%, significantly cutting down costs and enhancing supply chain efficiency.

Conclusion

Efficiently managing third-party inspections in China’s supply chain is a multifaceted challenge that requires strategic planning and collaboration. By laying out clear inspection criteria, aligning schedules with suppliers, adopting standardized reporting, fair cost allocation for re-inspections, and judiciously selecting an inspection partner, businesses can optimize this crucial process. This approach not only curtails costs but also fortifies the quality and reliability of the supply chain, a vital component in today’s competitive global market.