We provide Promotional Products quality control services in China

Our commitment to quality is unwavering, and we proudly offer specialized quality control services for promotional products in China. With a keen eye for detail and a dedication to excellence, we ensure that every promotional item meets the highest standards of quality and design, reflecting the true essence of your brand.

In a market where first impressions are crucial, our services play a pivotal role in maintaining the integrity and appeal of your promotional products. From meticulous inspection to compliance with international standards, we are dedicated to enhancing the value of your brand and ensuring that each product resonates with your target audience.

The key points of Promotional Products inspection

It will include thorough evaluations of material quality, construction and workmanship, size and fit, design and color accuracy, labeling and packaging, safety compliance, and overall aesthetic and finish.

Our inspection services involve a thorough examination of product appearance, durability, brand logo consistency, and compliance with safety standards, ensuring that each item not only meets aesthetic expectations but also upholds the highest levels of functionality and safety for end-users.

It will include thorough evaluations of material quality, construction and workmanship, size and fit, design and color accuracy, labeling and packaging, safety compliance, and overall aesthetic and finish.

Our inspection services involve a thorough examination of product appearance, durability, brand logo consistency, and compliance with safety standards, ensuring that each item not only meets aesthetic expectations but also upholds the highest levels of functionality and safety for end-users.

Appearance and style

The process entails a comprehensive evaluation of the product's style to confirm it aligns with the intended order requirements and client’s specification. This includes checking for color accuracy, design alignment, and overall aesthetic appeal to ensure it matches the predetermined specifications and brand identity.

The inspectors meticulously compare the products against approved samples or detailed style guides, paying close attention to textures, finishes, and any specific design elements that are critical to the brand's image.

Material

Inspectors are required to verify whether every type of material used in the product meets the specifications outlined in the order. For products that require specific material qualities, like water resistance or flame retardancy, specialized tests are conducted to confirm these attributes.

Additionally, material verification includes confirming the compliance of materials with relevant safety and environmental standards. This involves checking for the presence of harmful substances, ensuring adherence to regulations like REACH or RoHS in applicable regions.

Workmanship

Sampling

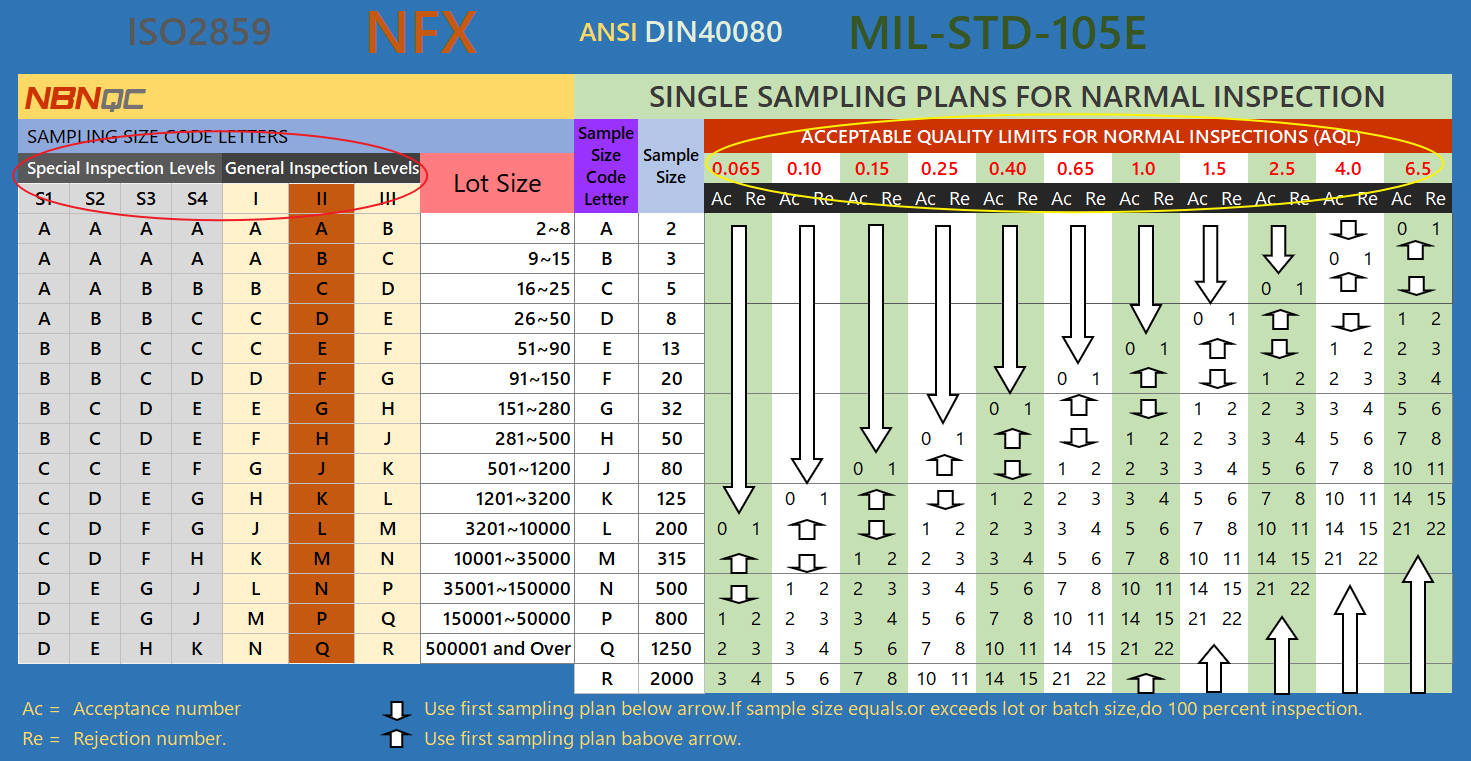

The number of samples for random inspection is determined based on the INSPECTION LEVELS requested by the client and the LOT SIZE of the goods. Then, find the corresponding AQL on the table. For example, if the required INSPECTION LEVEL is II, AQL is 0/2.5/4.0, and the LOT SIZE is 5000 pcs, then 200 pcs will be randomly sampled. The acceptable range for the number of defects is Critical 0 pcs/Major 10 pcs/ Minor 14 pcs. If the number of defects exceeds these limits, the goods will be rejected.

(Default: Inspection level II, AQL 0/2.5/4.0)

Quality check

Each sample selected for random inspection is individually examined, and all defective products are identified and segregated. These defective products are then categorized and quantified. This result determines whether the entire batch of goods falls within the AQL (Acceptance Quality Limit) range and is the key basis for deciding whether to accept or reject the shipment.

Classification of defects in promotional products

Critical Defects

-Safety hazards (sharp edges, choking hazards).

-Significant discrepancies in branding elements like logos

Major Defects

-Noticeable color mismatches.

-Significant printing errors or misalignments.

-Material flaws that affect durability or functionality.

-Minor deviations in dimensions that affect usability.

Minor Defects

-Minor scratches or marks not easily visible.

-Slight color variations within acceptable limits.

-Minor inconsistencies in stitching or finishing.

-Small printing imperfections that do not detract from the overall appearance.

Size Measurement

Key dimensions like length, width, height, and diameter are measured, along with specific features relevant to the product's design, such as the size of logos or print areas. It's crucial to compare these measurements against the specifications provided in the order or the approved sample. Any deviation beyond the accepted tolerance levels should be noted as a defect.

Label & Logo

Inspectors should closely examine the labels and logos for accuracy in color, size, placement, and font against the approved design specifications or reference samples. The quality of printing or embroidery, depending on the method used, should also be assessed for clarity and durability.

Additionally, inspectors must ensure that all required information, such as product composition, care instructions, or compliance symbols, are present and legible on the labels. Photographic documentation of labels and logos is recommended to provide a clear record of the inspection findings.

Packing & Packaging

This includes checking the thickness and strength of boxes, the integrity of seals, and the adequacy of cushioning materials. The packaging's size and shape should be assessed to ensure efficient and safe handling.

Additionally, inspectors need to verify that all packaging complies with branding requirements, including shipping mark, accurate logos, color schemes, and any necessary product information or instructions.

Common Tests of Promotional Products inspection

-

Carton assortment check

-

Needle Damage & Seam strength check

-

Symmetry check

-

Color shading check

-

Sticker test

-

Stretch test (for elastic and knitted fabric)

-

Fatigue test

-

Adhesive test

-

Rub test

-

Per inch stitches check

-

Barcode scan test

-

Carton drop test

-

Flame retardant test

-

Water proof test