We provide Makeup Tools quality control services in China

We specialize in providing top-tier quality control services for makeup tools in China, ensuring that every brush, sponge, and applicator meets the highest standards of safety, efficacy, and craftsmanship. Our meticulous inspection process covers everything from material quality to functional design, guaranteeing that each product not only enhances the beauty routine but also upholds the stringent health and safety regulations. Partnering with us means entrusting your products to experts dedicated to maintaining excellence in the dynamic world of beauty tools.

The key points of Makeup Tools inspection

The inspection process revolved around a thorough evaluation of material safety, structural integrity, functional efficacy, and compliance with regulatory standards. This process includes testing for harmful substances, ensuring durability and ergonomic design, verifying performance under various conditions, and adherence to industry-specific safety protocols. Our meticulous inspection ensures that each makeup tool not only meets aesthetic expectations but also prioritizes user safety and product longevity, reflecting the highest quality standards in the beauty industry.

Appearance and style

This begins with a detailed comparison of the appearance and color against the provided design specifications or prototypes. Inspectors examine each aspect of the tool's design, such as the shape of brush heads, the design of handles, and any specific features that are unique to the product. Additionally, Pantone color charts can be used to compare the colors of the products to see if they meet client’s specification.

In terms of size, precise measurements are taken using calipers or other precision measuring tools to check dimensions like length, width, and thickness. This process confirms that the dimensions of each tool fall within the acceptable tolerance range specified in the design requirements, ensuring functional ergonomics and aesthetic consistency.

Material

It will involves assessing the quality, safety, and suitability of the materials used in manufacturing. Inspectors check for the type and grade of materials, such as synthetic or natural bristles for brushes, plastic or metal for handles, and sponges' density and porosity.

It encompasses a series of safety and performance tests. the aim is to ensure that the materials not only meet the specifications of the client but also meet the industry's health and safety requirements.

Workmanship

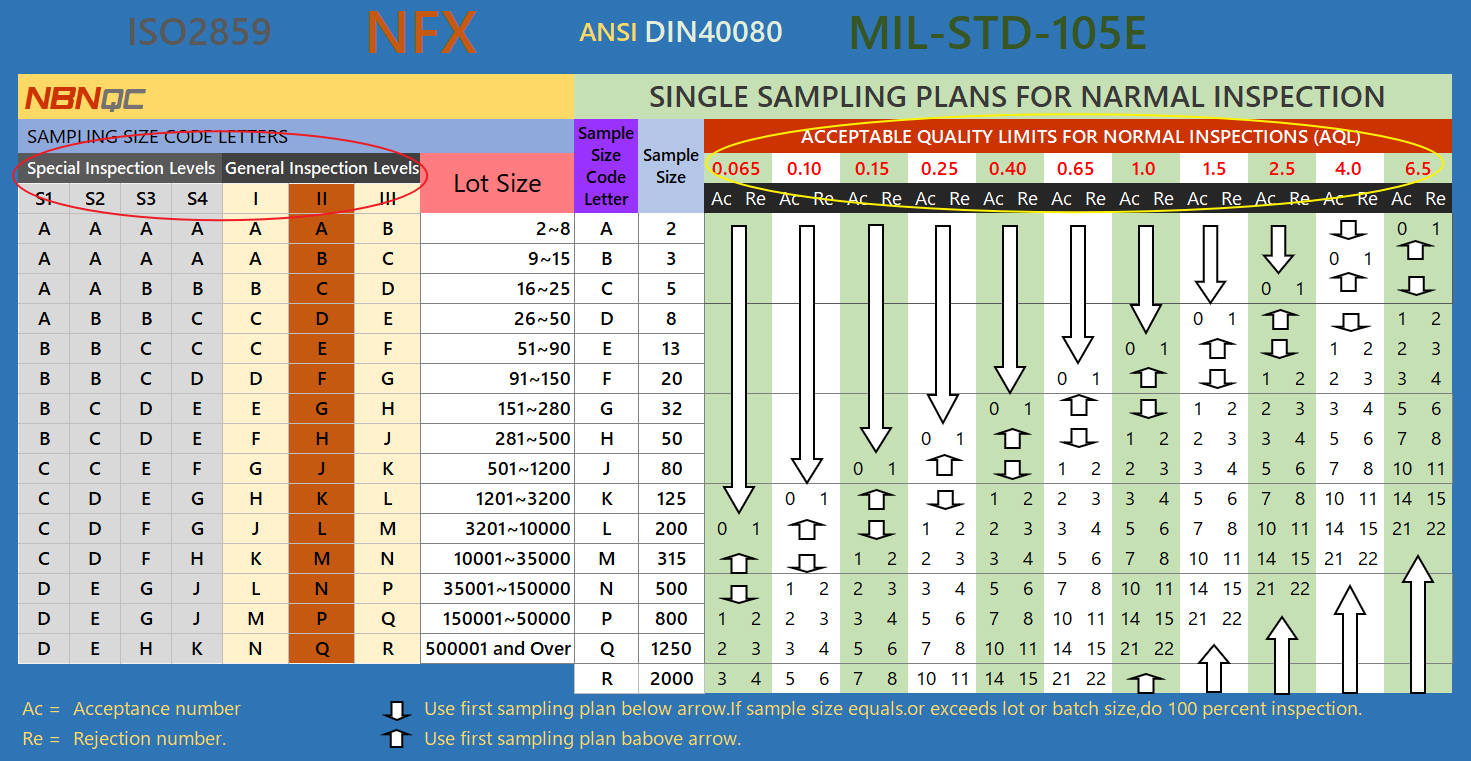

Sampling

The number of samples for random inspection is determined based on the INSPECTION LEVELS requested by the client and the LOT SIZE of the goods. Then, find the corresponding AQL on the table. For example, if the required INSPECTION LEVEL is II, AQL is 0/2.5/4.0, and the LOT SIZE is 5000 pcs, then 200 pcs will be randomly sampled. The acceptable range for the number of defects is Critical 0 pcs/Major 10 pcs/ Minor 14 pcs. If the number of defects exceeds these limits, the goods will be rejected.

(Default: Inspection level II, AQL 0/2.5/4.0)

Quality check

Each sample selected for random inspection is individually examined, and all defective products are identified and segregated. These defective products are then categorized and quantified. This result determines whether the entire batch of goods falls within the AQL (Acceptance Quality Limit) range and is the key basis for deciding whether to accept or reject the shipment.

Classification of defects in makeup tools

Critical Defects

-Safety hazards: Such as sharp edges or broken parts that could injure the user.

-Functional failure: Completely unusable or severely impacts the product's basic function.

-Severe material flaws: Use of prohibited or toxic substances.

-Significant design errors: Drastic deviations from design specifications or customer-specific requirements.

Major Defects

-Significant aesthetic flaws: Such as noticeable inconsistencies in color, shape, or printing.

-Minor functional issues: Affects normal use of the product but doesn’t render it completely ineffective.

-Quality instability: Parts that are prone to damage or looseness.

-Minor dimensional deviations: Exceeding normal tolerance limits but not affecting safety and main functionality.

Minor Defects

-Minor cosmetic imperfections: Like slight scratches, stains, or minor color variations.

-Small size or shape variances: Within acceptable tolerance limits but not meeting ideal standards.

-Minor packaging flaws: Such as slight damage to packaging or printing errors, not affecting the product quality itself.

Label & Logo

Verifying labels and logos involves a meticulous examination to ensure accuracy and compliance. This process includes checking the placement, size, and clarity of the logo, ensuring it matches the specified design and is free from printing errors or smudges. Labels are scrutinized for correct information, such as product name, brand details, manufacturing location, and any required compliance markings or symbols.

Packing & Packaging

A thorough evaluation to ensure protection, compliance, and presentation. This step includes checking the durability and suitability of packaging materials to protect the product during shipping and handling.

The packaging is also reviewed for compliance with legal and environmental standards, including the presence of necessary labels and warnings. All printing, including patterns, text and barcode must conform to the client’s specification.

Common Tests of Makeup Tools inspection

-

Carton assortment check

-

Smell test

-

Durability and Stress Test

-

Function Test

-

Color Fastness Test

-

Adhesive test

-

Barcode scan test