We provide Furniture quality control services in China

NBN offer specialized furniture quality control services in China, tailored to our clients' specific needs. Our exceptional team of quality engineers and inspectors conducts thorough Factory Audits, Pre-Shipment Inspections, During Production Inspections, and Initial Production Inspections, ensuring the highest quality standards for your furniture supply chain.

The key points of Furniture quality inspection

These include assessing the durability and stability of the furniture, checking for defects in materials and workmanship, verifying dimensions and alignment, and ensuring compliance with safety and environmental regulations. Inspectors also evaluate the aesthetics, such as finish quality and color consistency, and test the functionality of moving parts.

Appearance and style

Inspectors rigorously assess furniture design elements, comparing each selected sample to its design prototype or client’s specifications. Key factors like color, proportions, decorative details, and overall aesthetic balance are closely examined to ensure the furniture accurately reflects the intended style and meets customer expectations.

Proper Lighting Conditions: Ensure that the color inspection is conducted under sufficient and appropriate lighting. Natural light is the best option, but if not possible, artificial light that mimics natural light can be used. Different light sources (daylight, fluorescent, incandescent) can affect how colors appear.

Material

During furniture inspection, inspectors conduct an in-depth examination of the materials, including wood, metal, and fabric, to verify their compliance with specified quality grades and standards. They evaluate key properties like durability and strength, and test resistance to environmental stressors such as moisture and heat, ensuring each material is fit for purpose and contributes to the furniture's overall quality and resilience.

Workmanship

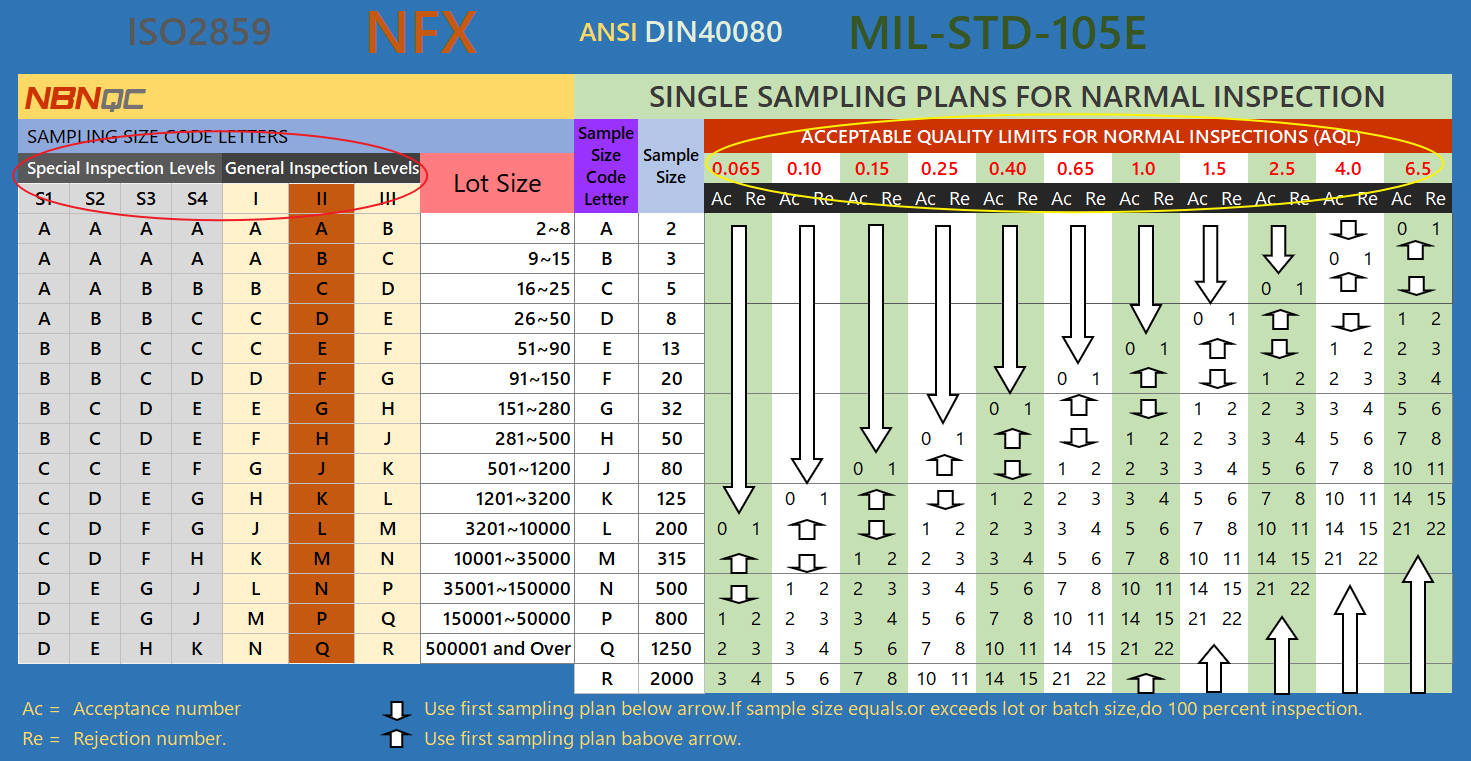

Sampling

The number of samples for random inspection is determined based on the INSPECTION LEVELS requested by the client and the LOT SIZE of the goods. Then, find the corresponding AQL on the table. For example, if the required INSPECTION LEVEL is II, AQL is 0/2.5/4.0, and the LOT SIZE is 5000 pcs, then 200 pcs will be randomly sampled. The acceptable range for the number of defects is Critical 0 pcs/Major 10 pcs/ Minor 14 pcs. If the number of defects exceeds these limits, the goods will be rejected.

(Default: Inspection level II, AQL 0/2.5/4.0)

Quality check

Each sample selected for random inspection is individually examined, and all defective products are identified and segregated. These defective products are then categorized and quantified. This result determines whether the entire batch of goods falls within the AQL (Acceptance Quality Limit) range and is the key basis for deciding whether to accept or reject the shipment.

Classification of defects in furniture

Critical Defects

These are the most severe defects that pose a safety hazard or render the furniture completely unusable. Examples include structural failures, sharp edges or splinters, and non-compliance with safety regulations.

Major Defects

Major defects significantly affect the functionality, durability, or aesthetic appeal of the furniture but do not pose a safety risk. These can include large cracks or splits, significant color mismatches, or major issues with moving parts (like drawers or hinges not operating correctly).

Minor Defects

Minor defects are small imperfections that do not significantly affect the furniture's functionality or overall appearance. Examples include minor scratches, small stains, or slight color variations.

Size Measurement

Measuring dimensions involves using precise tools like tape measures and calipers to ensure each piece matches its design specifications. Inspectors measure lengths, widths, heights, and depths, and compare these to blueprint standards, checking for uniformity and symmetry. They also verify internal dimensions for functionality and ensure measurements fall within acceptable manufacturing tolerances.

Label & Logo

Inspectors ensure that labels and logos are correctly positioned as per the design specifications, and they assess the quality of printing or embossing for legibility and durability. They also verify that the information on labels, such as brand name, care instructions, material composition, and manufacturing details, is accurate and complies with relevant regulations and standards.

Packing & Packaging

Inspectors check the strength and durability of boxes, wrapping materials, and cushioning to guard against damage. They also ensure that the packaging size and design are appropriate for the furniture's dimensions and weight. Additionally, inspectors verify the presence of necessary labels and handling instructions on the packaging to facilitate safe and efficient transportation.

Common Tests of furniture inspection

-

Humidity test

-

Stability test

-

Burrs and sharp corners check

-

Function test

-

Carton drop test

-

Barcode scan test