When importing goods from China, one of the key steps to ensure quality and compliance with international standards is conducting a Pre-shipment Inspection (PSI). This process plays a critical role in mitigating risks, ensuring that the products meet your specifications, and preventing costly surprises post-shipment. In this article, we will explore the importance of pre-shipment inspections, how they work, and why businesses should prioritize them when sourcing products from China.

Contents

- 1 What is Pre-shipment Inspection (PSI)?

- 2 Why is Pre-shipment Inspection Important?

- 3 How Does Pre-shipment Inspection in China Work?

- 4 Key Elements of a Pre-shipment Inspection in China

- 5 Benefits of Using a Third-Party Inspection Company

- 6 Common Mistakes to Avoid During Pre-shipment Inspections

- 7 Conclusion

What is Pre-shipment Inspection (PSI)?

Pre-shipment Inspection in China is a quality control process conducted before goods are shipped to the buyer. The goal is to verify that the products meet the agreed-upon specifications, quality standards, and regulations before they leave the factory. A PSI is typically performed when the production is complete, and the goods are ready for export. It’s a vital step in ensuring that there are no discrepancies between the goods you ordered and what is actually being shipped.

Why is Pre-shipment Inspection Important?

- Ensures Product Quality

A pre-shipment inspection helps to verify that the products meet the required quality standards, reducing the chances of receiving faulty or substandard goods. The inspection checks product functionality, packaging quality, labeling, and the overall appearance of the goods. - Reduces the Risk of Non-Compliance

Different countries have specific regulations and standards that products must meet to be imported. A PSI ensures that your goods comply with these regulations, reducing the risk of customs delays, fines, or product rejection at the destination port. - Minimizes Financial Risks

By identifying issues before shipment, a PSI allows for corrective actions to be taken before the goods leave the factory. This can help avoid costly returns, rework, or loss of reputation due to non-compliant or damaged goods arriving at the destination. - Peace of Mind

Knowing that a third-party inspection company has reviewed your goods before they are shipped provides peace of mind. It confirms that the goods meet both your expectations and those of any regulatory authorities involved.

How Does Pre-shipment Inspection in China Work?

- Inspection Planning

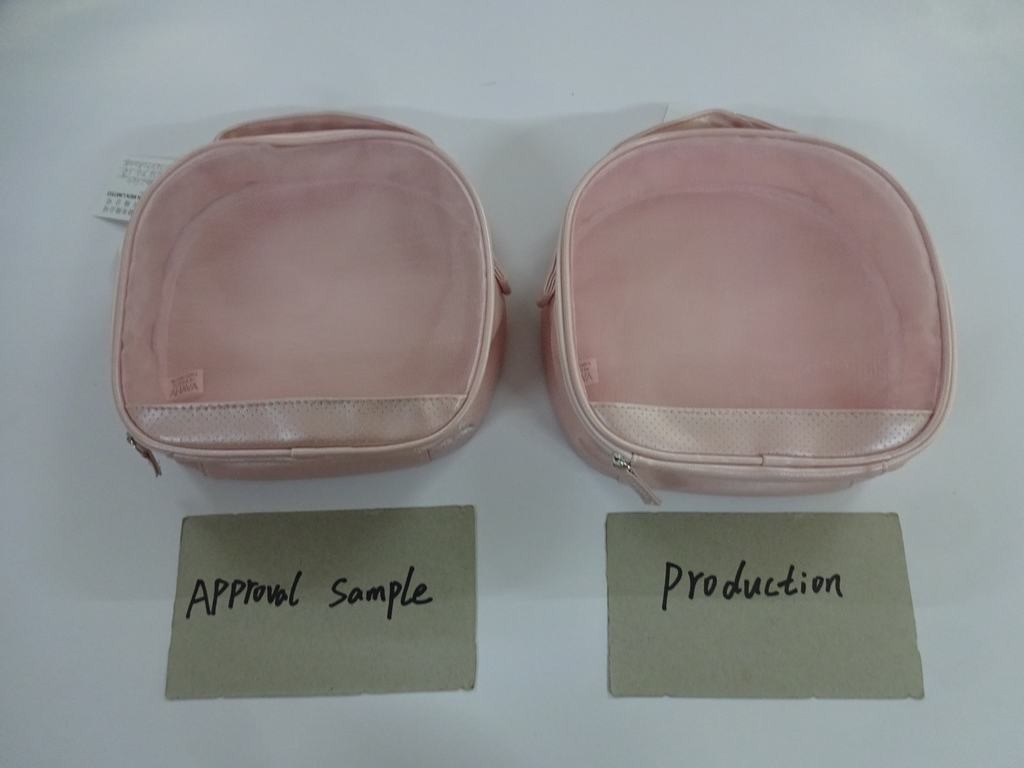

Before the inspection, the buyer and inspection agency agree on the scope, standards, and criteria to be followed. This includes the sampling plan, which specifies the number of items to be checked and the areas of focus (such as product quality, packaging, and labeling). - On-Site Inspection

An inspector visits the manufacturing site in China and inspects the goods based on the agreed-upon criteria. This includes evaluating product quality, quantity, packaging, and labeling, among other factors. - Inspection Report

After the inspection, the inspection agency provides a detailed report that outlines the findings, including photographs and any issues discovered. The report also includes recommendations for any corrective actions if necessary. - Decision

Based on the inspection findings, the buyer can decide whether to accept or reject the shipment, or if further adjustments are needed before shipment.

Key Elements of a Pre-shipment Inspection in China

- Quality Control: Verifying that products meet the required specifications and functionality.

- Quantity Check: Ensuring that the correct number of products are produced and packed.

- Packaging Inspection: Confirming that packaging meets both product protection and branding standards.

- Labeling and Documentation: Ensuring labels and accompanying documentation comply with regulatory requirements.

- Compliance Verification: Ensuring the products meet international or regional standards, such as CE, RoHS, or FDA compliance.

Benefits of Using a Third-Party Inspection Company

While some companies may choose to perform inspections internally, partnering with a third-party inspection company provides several advantages:

- Expertise: Third-party inspectors have specialized knowledge in product inspection and are familiar with international standards.

- Impartiality: As an independent third party, they can provide an unbiased, objective view of the product’s quality.

- Efficiency: A reliable inspection company can conduct thorough checks quickly, allowing for timely decisions and reducing delays.

Common Mistakes to Avoid During Pre-shipment Inspections

- Not Defining Clear Specifications: Always ensure that the quality standards and product specifications are clearly communicated to the supplier before the inspection.

- Neglecting to Inspect Product Samples: Inspecting a sample is often not enough; it’s crucial to conduct random checks on the final batch.

- Ignoring Packaging and Documentation: Ensuring that the packaging and labeling are compliant with export and import requirements is as important as the product quality itself.

Conclusion

Pre-shipment inspection in China is an essential part of the import-export process, offering both financial protection and peace of mind. By ensuring your products meet quality standards and compliance regulations before they leave China, you can minimize risks and avoid costly mistakes. Whether you are sourcing electronics, textiles, or consumer goods, a reliable pre-shipment inspection is your safeguard against quality issues and compliance failures.

If you’re looking to improve the quality control of your goods sourced from China, it’s highly recommended to partner with a professional inspection agency to ensure that your products meet all expectations and regulations.