Remark: The “MAJOR DEFECTS” mentioned here refer to defects that occur at a high proportion or on a large scale.

Pre-shipment inspections (PSI) are a critical step in the quality control process, ensuring that products meet buyer requirements and quality standards before shipment. However, in some cases, major defects may be identified during the inspection, potentially affecting the shipment and causing significant delays. So, what should a buyer or inspection team do when major defects are found during a pre-shipment inspection?

This article will discuss how to handle major defects during pre-shipment inspections, offering practical steps for resolving issues and ensuring that the final product meets quality standards.

Contents

- 1 What Are Major Defects in Pre-Shipment Inspections?

- 2 Immediate Actions When Major Defects Are Found

- 3 Determining the Root Cause of the Defects

- 4 Exploring Possible Solutions

- 5 Re-inspection of Corrected Products

- 6 Updating Documentation and Quality Control Records

- 7 Preventing Future Defects: Continuous Improvement

- 8 Conclusion

What Are Major Defects in Pre-Shipment Inspections?

Major defects are those that significantly affect the usability, functionality, or aesthetic of the product. These defects often render the product unsuitable for use or could lead to safety hazards. Examples of major defects include:

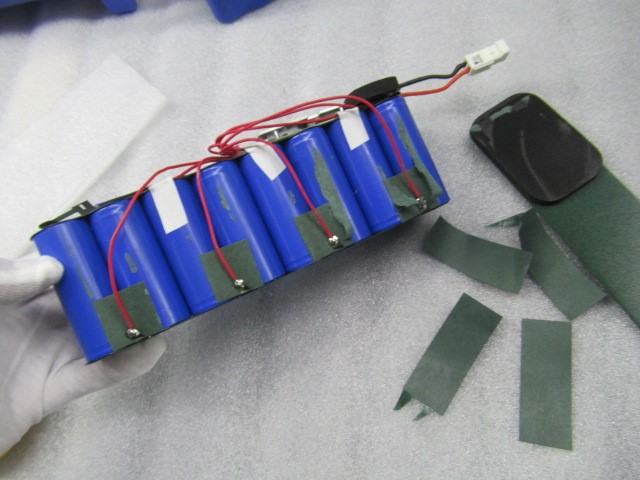

- Functional failures (e.g., electronic devices not working as intended)

- Serious cosmetic damage (e.g., cracks, discoloration, or severe scratches)

- Missing or incorrect parts

- Non-compliance with safety standards or regulations

In a pre-shipment inspection, any batch found with these types of defects should be carefully evaluated and addressed before moving forward.

Immediate Actions When Major Defects Are Found

Upon discovering major defects, it’s essential to take immediate and structured actions to prevent defective products from reaching the buyer. Here are the initial steps to follow:

a. Halt Shipment

As soon as major defects are identified, halt the shipment of the affected batch. This prevents defective products from entering the market and causing damage to your brand reputation.

b. Assess the Defects

Conduct a thorough evaluation of the defect. Is the defect isolated to a few items, or does it affect the entire batch? Record the defects in detail, including photographs, videos, and any other documentation that can serve as evidence of the issue.

c. Notify the Supplier and Buyer

It’s crucial to keep both the supplier and buyer informed of the issue. Send them a detailed report explaining the discovered defects, their possible causes, and the extent of the problem. Maintain clear communication to ensure both parties are on the same page and can discuss the best course of action.

Determining the Root Cause of the Defects

Understanding the root cause of the major defects is essential for finding an effective solution. This could involve:

- Reviewing the production process: Was there an issue with manufacturing, assembly, or packaging that led to the defects?

- Examining the raw materials: Were the materials substandard or incorrect for the product specifications?

- Testing equipment and tools: Were the equipment used to produce the goods malfunctioning or improperly calibrated?

By conducting a root cause analysis, you can determine whether the problem was due to a production flaw, supplier error, or an issue with materials.

Exploring Possible Solutions

Once the defects are identified and the root cause is understood, there are several options to address the situation:

a. Rework or Repair

If the defects are repairable or can be fixed without affecting the product’s quality, arrange for the supplier to correct the issue. This may involve reworking the damaged items or replacing parts that were defective. Ensure that the rework process follows the quality standards agreed upon with the buyer.

b. Product Replacement

If the defects are too severe or widespread, the best option may be to replace the defective items with new ones. Work with the supplier to produce replacement products that meet the required specifications and quality standards.

c. Price Reduction or Discount

In cases where the defects are minor, and the buyer is still willing to accept the goods with some imperfections, negotiate a price reduction or discount as compensation. Be sure to document these agreements in writing to avoid any future disputes.

Re-inspection of Corrected Products

After any defects are addressed, the corrected products should undergo a re-inspection. This ensures that the rework, repairs, or replacements meet the required standards before shipping. Conduct another round of inspections to ensure that the quality is now up to par.

Updating Documentation and Quality Control Records

Once the issue is resolved, update all related documentation and quality control records. This includes:

- Inspection reports

- Corrective action reports

- Correspondence with the supplier and buyer

Keeping a detailed record of all actions taken ensures transparency and helps prevent future quality issues. It also allows for proper tracking in case of recurring issues.

Preventing Future Defects: Continuous Improvement

Handling major defects effectively is crucial, but it’s also important to implement measures to prevent similar issues in the future. Here are a few strategies to consider:

- Supplier Audits: Regularly audit your suppliers’ production facilities to ensure they comply with quality standards.

- Improved Communication: Foster open lines of communication between buyers, suppliers, and quality inspectors to ensure clear understanding of product requirements and standards.

- Enhanced Quality Control: Implement stricter quality control measures at each stage of the production process to catch defects early and minimize issues during the pre-shipment inspection.

Conclusion

Major defects discovered during pre-shipment inspections can be a serious concern, but with the right approach, they can be resolved effectively. By halting shipment, assessing the issue, working with the supplier to implement corrective actions, and ensuring that quality control measures are followed, you can protect both your brand reputation and your relationship with your buyer.