When it comes to chalk products, whether for educational, industrial, or artistic use, quality and safety are paramount. For manufacturers, distributors, and buyers, ensuring that chalk meets high-quality standards is crucial. This is where inspection services in China come into play, providing thorough evaluation of chalk quality to meet both local and international standards. This article delves into the safety concerns, classifications, international standards, and methods used in chalk quality inspection.

Contents

The Safety of Chalk Products

Chalk, commonly used in schools and classrooms worldwide, is typically composed of calcium carbonate. While it is generally safe for educational and industrial purposes, safety concerns arise if the product contains harmful additives or impurities, especially for children. Substandard chalk can cause respiratory issues, skin irritation, or even lead to long-term health problems if exposed to harmful chemicals over time. That’s why it is essential to ensure chalk products meet safety requirements through proper inspection services.

Classification of Chalk Products

Chalk products can be classified into various categories based on their usage and material composition:

- School Chalk – Traditional white chalk, commonly used in classrooms for blackboards. These are often made from gypsum or calcium carbonate.

- Artistic Chalk – Typically softer, used for drawing and artwork. These may include various color pigments and may be made from a blend of materials such as gypsum, clay, and chalk.

- Industrial Chalk – Often larger, more durable chalk used for marking in construction, engineering, and similar sectors. These may be made from a blend of different minerals to ensure durability and effectiveness.

- Chalk for Special Purposes – For instance, chalk used in sports like billiards (cue chalk) or in other specialized fields like carpentry or masonry.

Each of these classifications requires different safety standards and material specifications, making thorough chalk quality inspection essential.

International Standards for Chalk Products

Several international standards govern the quality and safety of chalk products. These standards ensure consistency in product quality, materials used, and overall safety. Some of the key global regulations include:

- ISO 9001 – This quality management system standard ensures that products meet customer and regulatory requirements. For chalk, it ensures consistency in manufacturing processes.

- REACH (Registration, Evaluation, Authorisation, and Restriction of Chemicals) – A European Union regulation ensuring that chemicals used in products (including chalk) do not harm human health or the environment.

- ASTM D2564 – A standard that governs the performance of chalk for educational use in the U.S., ensuring non-toxicity and ease of use.

- CE Marking – A certification mark that indicates conformity with health, safety, and environmental protection standards for products sold within the European Economic Area.

Compliance with these international standards requires rigorous testing and quality control processes that are integral to chalk quality inspection services.

How Chalk Quality Inspection Works

To ensure that chalk products meet all safety and quality requirements, a detailed chalk quality inspection process is carried out. Here are the key steps involved:

- Material Testing – The first step in inspection is to analyze the raw materials used to make the chalk. This includes testing for harmful substances like lead, cadmium, or asbestos, as well as ensuring that the chalk contains the correct mineral composition (such as calcium carbonate or gypsum).

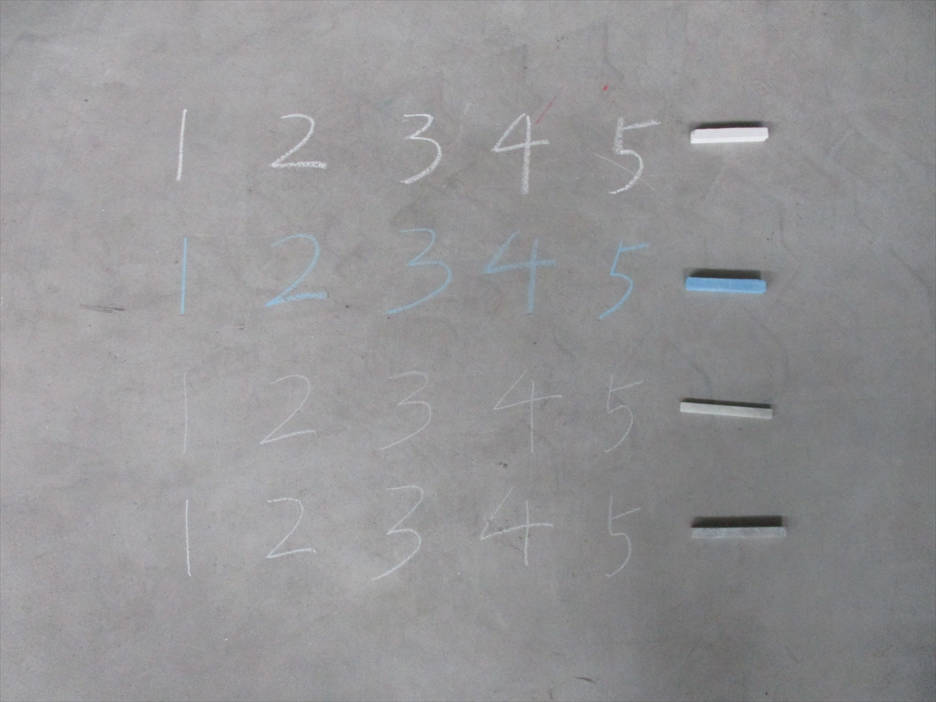

- Physical Inspection – This step involves checking the physical properties of the chalk, such as size, weight, shape, and texture. For educational chalk, the hardness and smoothness are especially important for ease of writing and reducing dust production.

- Toxicity Testing – For safety, the chalk is tested for any potential harmful chemicals or toxins that could be harmful upon contact with skin or if inhaled. Toxicity testing also ensures compliance with REACH and ASTM standards.

- Durability Testing – For industrial chalk or any product designed to withstand rough use, durability tests are conducted. This may include testing for wear and tear, color retention, and resistance to breaking under pressure.

- Packaging and Labeling Verification – The packaging and labeling are also inspected to ensure that all safety instructions, ingredients, and certification marks (such as CE or ISO) are correctly displayed. Clear labeling ensures that consumers are informed of any potential risks or handling instructions.

Why Use Chalk Quality Inspection Services in China?

China is a major producer of chalk products, and with the growing demand for both domestic and international markets, the need for reliable inspection services in China is greater than ever. By using professional inspection services, manufacturers can ensure that their products comply with both local and global safety standards, which can help avoid costly recalls and protect brand reputation.

Using inspection services in China provides several advantages:

- Expertise in Local Regulations – China has its own set of regulations for product safety and quality. Local inspection services are well-versed in these regulations and can ensure compliance.

- Access to International Standards – Professional inspectors in China are familiar with international standards, making it easier for manufacturers to export their products globally.

- Cost-Effective – Inspection services in China often offer cost-effective solutions for ensuring high-quality products without the overhead costs of international testing services.

Conclusion

Chalk quality inspection plays a crucial role in ensuring that products are safe, durable, and meet both local and international standards. With China being one of the largest producers of chalk products, utilizing inspection services in China guarantees that manufacturers can produce top-notch chalk that complies with regulatory requirements. Whether it’s school chalk, artistic chalk, or industrial chalk, a thorough quality inspection ensures that the product is safe, reliable, and ready for use.

By choosing a trusted inspection service, manufacturers can enhance the credibility of their chalk products and foster consumer trust, both locally and internationally.