We provide Houseware quality control services in China

We specialize in offering comprehensive houseware quality control services across China. Our expertise is tailored to ensuring that every home goods product meets the highest standards of quality and safety. From detailed inspections of kitchenware to rigorous testing of bathroom accessories, our team diligently works to safeguard the integrity of your products, helping your houseware brand maintain its reputation for quality in the global market.

The key points of Houseware inspection

Houseware inspection involves meticulous examination of physical and functional attributes of products like kitchenware, tableware and sanitaryware, ensuring they are defect-free, durable, and user-friendly. Additionally, it includes compliance with safety and quality regulations, testing for hazardous substances, and verifying labeling and packaging.

Appearance and style

Inspectors compare the actual products against pre-approved samples or detailed product specifications. They check for consistency in design elements, ensuring that the style, shape, and size of the products match the agreed-upon standards. For products with multiple components or variations, each item is meticulously reviewed to confirm uniformity in style.

In addition,inspectors use color swatches or Pantone color charts to ensure the colors of the houseware items match the specified hues. This is especially important for products that come in a range of colors or have color-dependent features. In some cases, inspectors might employ colorimeters or spectrophotometers for precise color matching, particularly when the color consistency is crucial for the product's appeal.

Material

Inspectors begin by reviewing the product specifications provided by the manufacturer, which detail the types of materials supposed to be used. They then physically examine the houseware items, comparing the actual materials against these specifications. This involves tactile assessments for texture and weight, visual inspections for material quality and finish, and sometimes even smell tests for chemical odors that might indicate substandard or hazardous materials.

Advanced testing methods are often employed to further verify the material composition of houseware products. This can include laboratory tests like spectrometry or chemical analysis, which are capable of accurately identifying the elemental composition of materials. Such tests are important for detecting the presence of harmful substances like lead in ceramics or BPA in plastics.

Workmanship

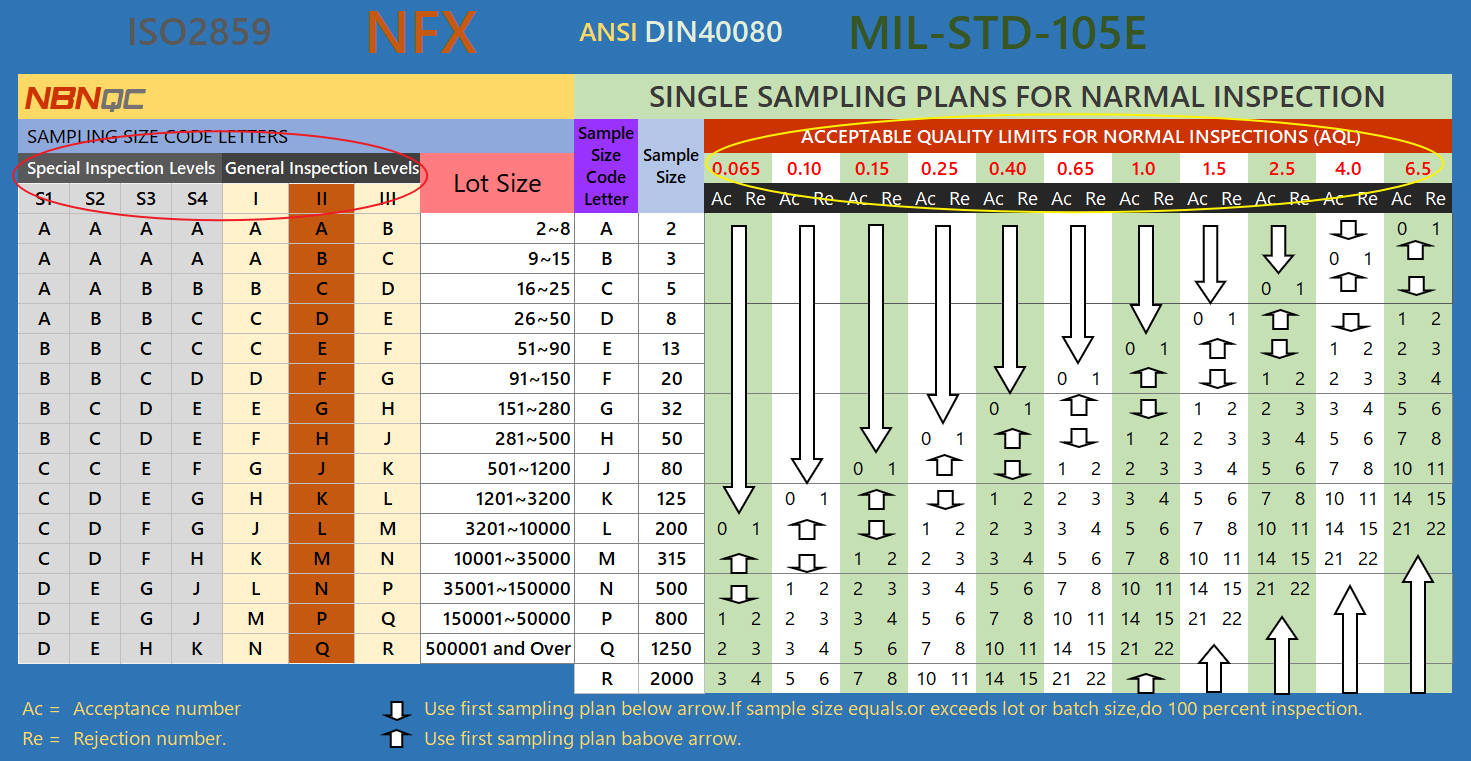

Sampling

The number of samples for random inspection is determined based on the INSPECTION LEVELS requested by the client and the LOT SIZE of the goods. Then, find the corresponding AQL on the table. For example, if the required INSPECTION LEVEL is II, AQL is 0/2.5/4.0, and the LOT SIZE is 5000 pcs, then 200 pcs will be randomly sampled. The acceptable range for the number of defects is Critical 0 pcs/Major 10 pcs/ Minor 14 pcs. If the number of defects exceeds these limits, the goods will be rejected.

(Default: Inspection level II, AQL 0/2.5/4.0)

Quality check

Each sample selected for random inspection is individually examined, and all defective products are identified and segregated. These defective products are then categorized and quantified. This result determines whether the entire batch of goods falls within the AQL (Acceptance Quality Limit) range and is the key basis for deciding whether to accept or reject the shipment.

Classification of defects in houseware

Critical Defects

These are defects that render the product unsafe or non-compliant with legal and regulatory standards. Critical defects pose a significant risk to the user's safety or health. For example, sharp edges on kitchenware, electrical faults in appliances, or the presence of hazardous materials like lead in ceramics.

Major Defects

These defects do not necessarily pose a safety risk but significantly affect the product's functionality, performance, or overall appearance. Major defects can include issues like significant color mismatches, substantial deviations from specified dimensions, or functional flaws that hinder the product's intended use.

Minor Defects

Minor defects are superficial flaws that do not affect the product's safety or functionality. These can include minor scratches, small color variations not easily noticeable, or slight imperfections in the finish.

Size Measurement

Inspectors use various tools such as rulers, calipers, and measuring tapes to accurately measure the length, width, height, and, in some cases, the thickness of the items. For more complex products or intricate designs, digital measuring devices like laser distance meters or digital calipers might be employed for greater precision. The measurements are then compared against the manufacturer's specifications or industry standards.

Label & Logo

Inspectors check for the correct placement, size, color, and design of the labels and logos on selected sample. They use the approved artwork or sample as a reference, comparing it meticulously with the labels and logos on the inspected items. This process includes verifying the legibility and accuracy of any printed information, such as product names, brand logos, care instructions, and compliance markings. The inspectors also check the quality of the label and logo application, ensuring that they are securely attached, free from smudging, and resistant to fading or peeling, which is essential for maintaining brand integrity and consumer trust.

Packing & Packaging

Evaluate the physical integrity and suitability of the packaging, checking for durability, material quality, and resistance to damage during transit. They ensure that the packaging aligns with the specified requirements, including the correct size, thickness, and type of materials used, such as cardboard, plastic, or foam.

The inspection also includes verifying the accuracy and completeness of any printed information on the packaging, like shipping marks barcodes, product descriptions, and handling instructions. For products requiring assembly, inspectors ensure that all necessary components are included and adequately secured within the package.

Common Tests of Houseware inspection

-

Carton assortment check

-

Waterproof test

-

Flame retardant test

-

Smell test

-

Color shading check

-

Function test

-

Pull test

-

Fatigue test

-

Adhesive test

-

Rub test

-

Carton drop test

-

Barcode scan test