We provide stationery quality control services in China

We specialize in delivering top-tier stationery quality control services across China, focusing on ensuring that every piece of stationery, from pens and pencils to notebooks and organizers, meets the highest standards of quality and safety. Our comprehensive approach encompasses detailed inspections and rigorous testing to guarantee that each product not only aligns with industry norms but also exceeds customer expectations in both functionality and durability.

The key points of stationery inspection

It will include assessing the physical and mechanical properties of products, verifying compliance with safety standards (like non-toxic materials and child safety regulations), checking for consistency in design and dimensions, ensuring the functionality and durability of items, and evaluating the overall aesthetic and finishing quality. These inspections are crucial to guarantee that the stationery products are safe, reliable, and meet both the legal requirements and consumer expectations.

Appearance and style

Inspectors compare the physical stationery items against pre-approved samples or detailed product specifications provided by the client. Special attention is given to the intricacies of the design, ensuring that even the most subtle elements align with the client's requirements. This step is crucial for maintaining design consistency and meeting the aesthetic expectations set forth by the brand or client.

Visually examine the products under standardized lighting conditions to ensure color consistency and to check for any discrepancies or fading. Additionally, if the client provides specific color codes, it is essential to use a Pantone color chart to verify the corresponding colors on the actual products and to record any deviations.

Material

A detailed review of the product specifications provided by the client, which includes a comprehensive list of materials that are supposed to be used in each stationery item. Inspectors compare these specifications against the actual products to ensure that the materials, such as types of paper, plastics, metals, and inks, match exactly what was stipulated. This verification process might involve tactile assessments to gauge texture and weight, visual inspections for color and finish, and sometimes even smell tests for materials like adhesives and inks, to ensure the correct materials are used.

Workmanship

Sampling

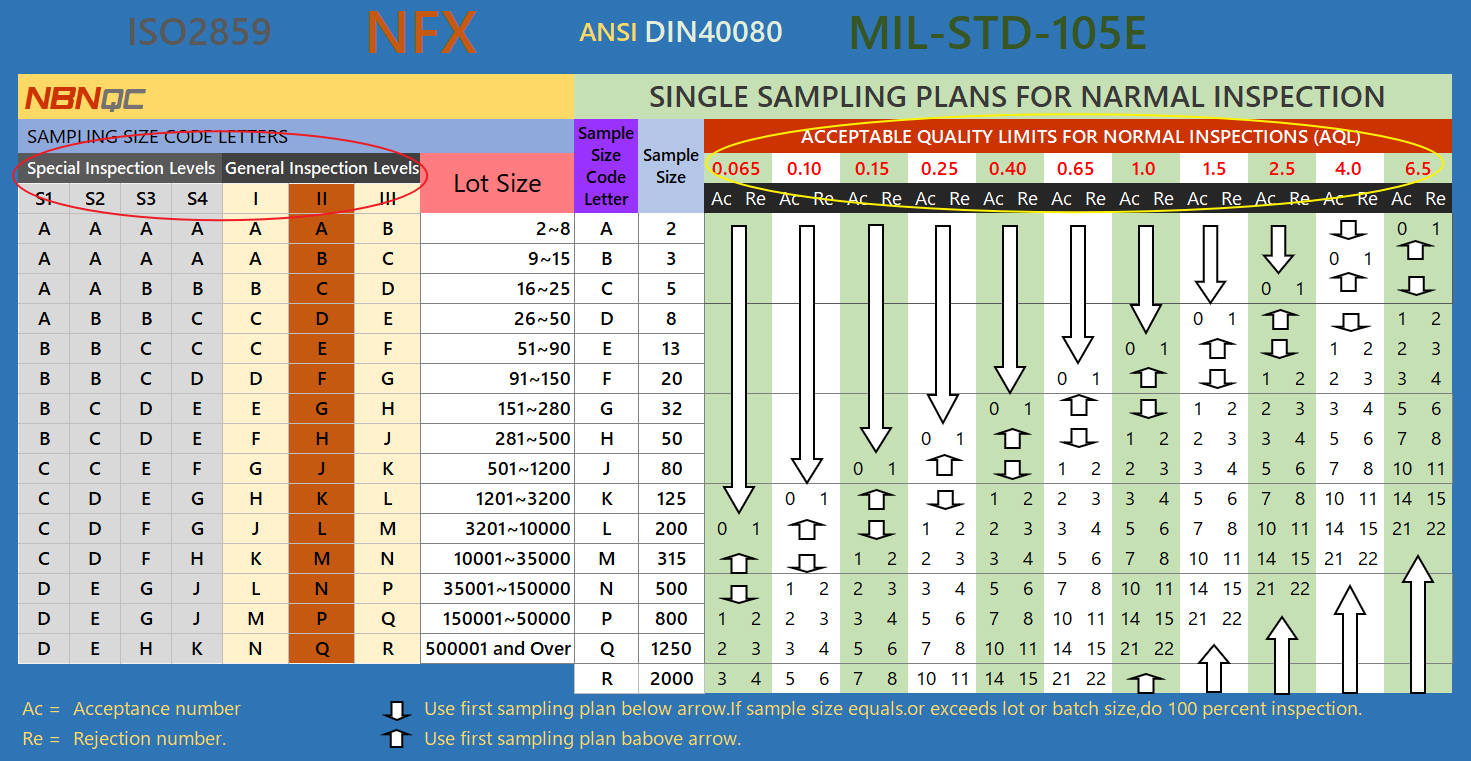

The number of samples for random inspection is determined based on the INSPECTION LEVELS requested by the client and the LOT SIZE of the goods. Then, find the corresponding AQL on the table. For example, if the required INSPECTION LEVEL is II, AQL is 0/2.5/4.0, and the LOT SIZE is 5000 pcs, then 200 pcs will be randomly sampled. The acceptable range for the number of defects is Critical 0 pcs/Major 10 pcs/ Minor 14 pcs. If the number of defects exceeds these limits, the goods will be rejected.

(Default: Inspection level II, AQL 0/2.5/4.0)

Quality check

Each sample selected for random inspection is individually examined, and all defective products are identified and segregated. These defective products are then categorized and quantified. This result determines whether the entire batch of goods falls within the AQL (Acceptance Quality Limit) range and is the key basis for deciding whether to accept or reject the shipment.

Classification of defects in stationery

Critical Defects

This could include the use of hazardous materials, sharp edges that could cause injury, or a design flaw that makes the product unsafe for its intended use.

Major Defects

Significant color mismatches, malfunctioning parts (like a pen that fails to write properly), or significant aesthetic flaws that affect the product's appeal or usability.

Minor Defects

Slight color variations that are not easily noticeable, minor misalignments in print, or small imperfections in the finish.

Size Measurement

Inspectors carefully measure key dimensions of the stationery products, such as length, width, height, and thickness, as per the client’s specifications or industry standards.

For complex or irregularly shaped items, additional tools like angle gauges or contour gauges might be used to ensure accuracy in measurement. The results are then compared against the predefined specifications to identify any deviations.

Label & Logo

Checking the accuracy of the logo's design, color, size, and placement on the product, ensuring it aligns perfectly with the brand's specifications. Additionally, inspectors review the labels for correct and clear information, including product name, company details, manufacturing information, and any necessary compliance markings or safety warnings.

Packing & Packaging

Check the quality and durability of packaging materials to ensure they are sturdy enough to protect the stationery during transportation and storage. This includes checking the thickness, strength, and quality of boxes, wrapping paper, or plastic casings. Additionally, verify the printed content such as shipping marks or warning labels on the export carton, patterns and text on the inner box, as well as the completeness of the products, accessories, and instruction manuals within the packaging.

Common Tests of Stationery inspection

-

Carton assortment check

-

Color shading check

-

Sticker test

-

Adhesive test

-

Rub test

-

Function test

-

Waterproof test

-

Flame retardant test

-

Smell test

-

Fatigue test

-

Carton drop test

-

Barcode scan test