We provide toys quality control services in China

NBN dedicated to upholding the highest standards of safety and craftsmanship in the toy industry. Our experienced team conducts detailed inspections and rigorous testing to ensure every product meets global safety norms and quality benchmarks. With a keen eye on both international and Chinese regulations, we offer customer and brands the assurance of impeccable quality, mitigating risks and enhancing customer satisfaction in the dynamic world of toys.

The key points of toys inspection

The inspection will involve a thorough assessment of safety, quality, and compliance. This includes checking for non-toxic materials, ensuring structural integrity, verifying age-appropriateness, and adherence to both international and local safety standards. Additional focus areas include functional testing to confirm the toy operates as intended, inspecting packaging for safety and informational accuracy, and conducting random sample checks to maintain consistent quality across production batches.

Appearance and style

Cross-referencing the product against the detailed design documents provided by the manufacturer, including technical drawings, color palettes, and model specifications. Inspectors meticulously compare the physical toy with these documents to confirm that the style, including shape, size, and features, precisely matches the intended design.

Material

Material verification includes reviewing manufacturers' specifications, conducting on-site checks and lab tests to confirm material quality, ensuring compliance with safety standards like EN71 or ASTM.

Auditing supply chains for standard adherence, maintaining continuous monitoring and detailed records, and partnering with certification agencies for independent testing. These steps ensure the materials used in toys meet necessary safety and quality standards.

Workmanship

Sampling

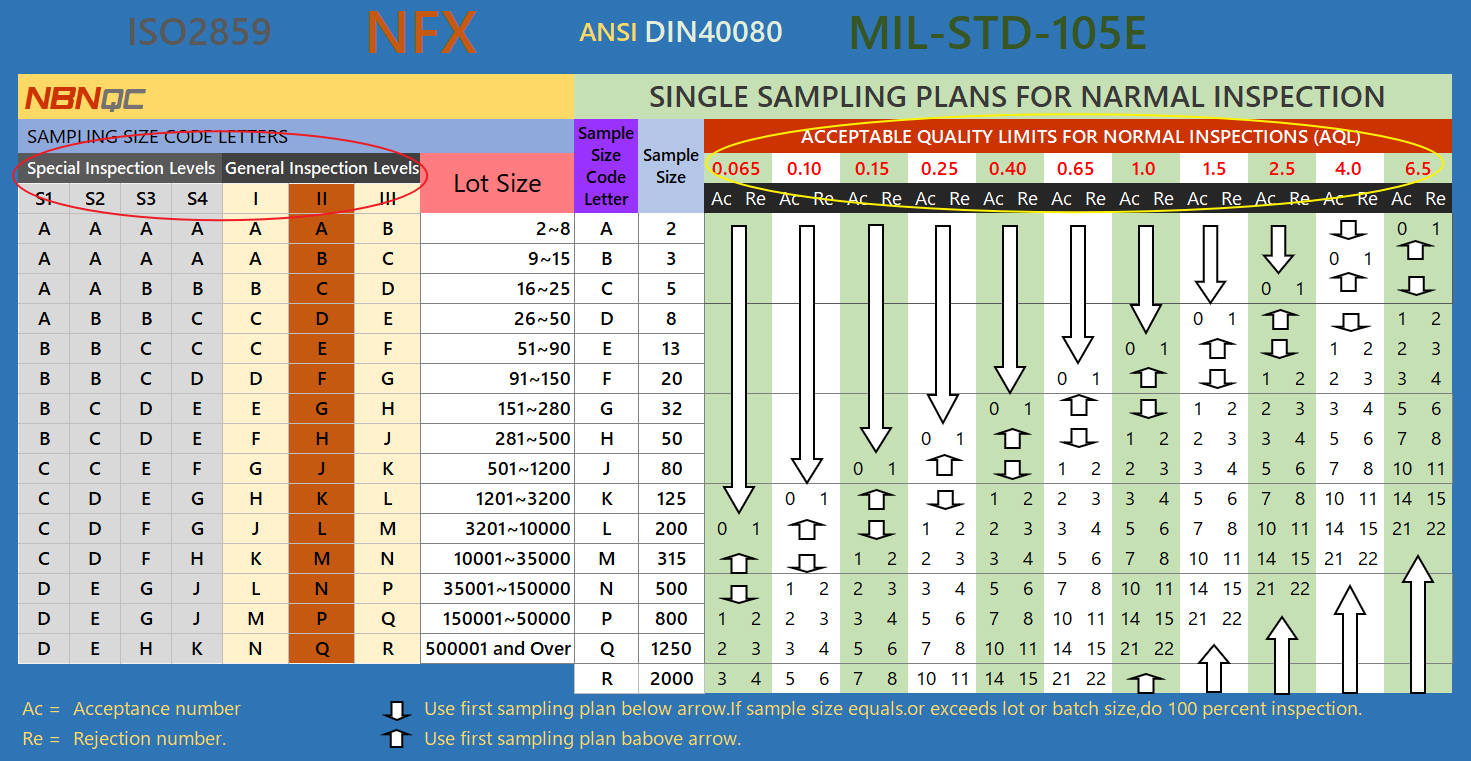

The number of samples for random inspection is determined based on the INSPECTION LEVELS requested by the client and the LOT SIZE of the goods. Then, find the corresponding AQL on the table. For example, if the required INSPECTION LEVEL is II, AQL is 0/2.5/4.0, and the LOT SIZE is 5000 pcs, then 200 pcs will be randomly sampled. The acceptable range for the number of defects is Critical 0 pcs/Major 10 pcs/ Minor 14 pcs. If the number of defects exceeds these limits, the goods will be rejected.

(Default: Inspection level II, AQL 0/2.5/4.0)

Quality check

Each sample selected for random inspection is individually examined, and all defective products are identified and segregated. These defective products are then categorized and quantified. This result determines whether the entire batch of goods falls within the AQL (Acceptance Quality Limit) range and is the key basis for deciding whether to accept or reject the shipment.

Classification of defects in toys

Critical Defects

These are the most severe type of defects, potentially posing a direct threat to user safety. Examples include sharp edges, easily detachable small parts, or materials containing toxic chemicals. Any detected critical defects lead to the rejection of the entire batch of products, as they violate safety standards.

Major Defects

Major defects usually involve non-safety aspects of the product but are severe enough to affect the overall appearance, functionality, or durability. These defects might include significant color discrepancies, functional malfunctions, or quality flaws such as loose stitching. While these defects do not directly threaten user safety, they can impact consumer satisfaction and the product's performance in the market.

Minor Defects

Minor defects are the least severe and typically do not significantly impact the overall use or appearance of the product. These might include minor scratches, slight color variations, or minor packaging flaws. Although these defects generally do not lead to product returns, an excessive number of minor defects may indicate quality control issues in the production process.

Size Measurement

Inspectors measured for key dimensions like length, width, height, and other relevant aspects as per the product specifications. It's important to measure multiple samples to ensure consistency in dimensions across the production batch.

All measurements are meticulously recorded and compared against the design specifications and tolerance to verify compliance.

Label & Logo

Closely examining the toy's label and logo against the brand's official design specifications. This includes checking for correct placement, size, color accuracy, and font style of the labels and logos. They ensure that all branding elements are clearly visible, legible, and accurately represent the manufacturer's intended design.

Additionally, inspectors verify that all required information, such as safety warnings, age recommendations, and manufacturer details, are present and correctly displayed on the label.

Furthermore, inspectors assess the quality and durability of labels and logos on the toys. This involves testing the adhesion of stickers or printed labels to ensure they are securely attached and do not peel off easily, which is especially important for toys intended for younger children.

Packing & Packaging

Inspectors check the durability and security of the packaging materials and design, ensuring compliance with regulatory and environmental standards. They verify that all necessary information, such as shipping marks, safety warnings, and country of origin on export carton. Additionally, they confirm that the printed content on the inner packaging matches the client's specifications and that each individual package contains complete products, accessories, and instructions.

Common Tests of Toys inspection

-

Carton assortment check

-

Function test

-

Smell test

-

Small object test

-

Flammability test

-

Waterproof test

-

Color shading check

-

Stretch test

-

Fatigue test

-

Adhesive test

-

Rub test

-

Barcode scan test