We provide Jewelry quality control services in China

We specialize in offering premium quality control services for jewelry brands in China, ensuring that each product adheres to the highest standards of excellence and craftsmanship. Our focus on detail and commitment to quality guarantees that jewelry items meet both global and industry-specific benchmarks, delivering unparalleled excellence to discerning clients worldwide.

The key points of Jewelry inspection

It will include verifying the authenticity and quality of materials, ensuring precision in craftsmanship, checking for defects or inconsistencies, confirming compliance with industry standards, and assessing the overall aesthetic appeal and finishing of each piece.

Authenticity and Quality of Materials

Physical examination involves using magnifiers or microscopes to scrutinize the cut and shape of jewelry. Chemical tests are conducted to determine the composition of metals and gemstones, such as acid tests for metal purity or spectrometry for gemstone analysis. Additionally, scrutiny of the supply chain is crucial in ensuring the ethical sourcing of materials and their compliance with brand specifications.

Furthermore, verifying the authenticity and accuracy of certification documents, like diamond certificates, is vital. These steps collectively ensure that the materials in jewelry are not only authentic but also meet high-quality standards.

Craftsmanship and Manufacturing Quality

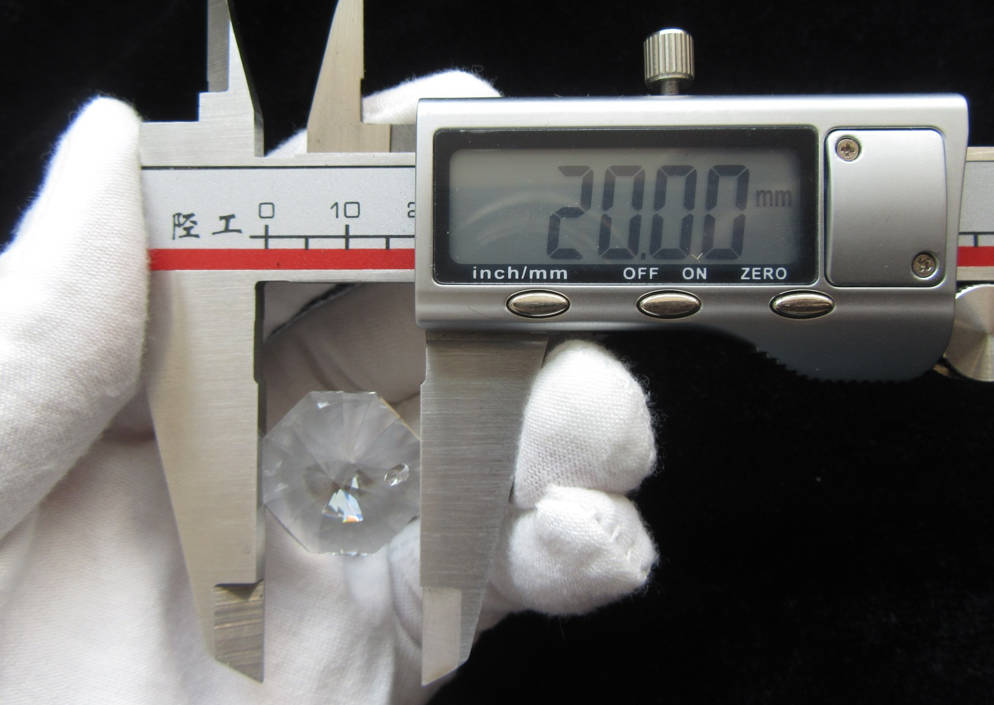

1. A visual inspection is conducted to examine the finesse and precision of the craftsmanship. This involves looking for uniformity in design, symmetry, and overall aesthetic appeal. Any signs of rough finishing, asymmetry, or deviation from the design specifications indicate a lapse in manufacturing quality. High-quality craftsmanship is characterized by meticulous attention to detail, seamless construction, and an impeccable finish.

2. The physical integrity of the item is assessed. This includes checking the strength and stability of joints, clasps, and settings in jewelry, and ensuring that moving parts like watches or mechanical accessories function smoothly. Durability tests may be performed to see how the item withstands stress or wear over time.

3. Advanced techniques such as 3D imaging or X-ray fluorescence (XRF) analysis might be used to inspect the internal structure of the item, which is particularly important for complex pieces. These technologies can reveal hidden flaws or inconsistencies that are not visible to the naked eye.

4. Comparison with brand standards and previous models is crucial. This involves checking if the item adheres to the established quality benchmarks of the brand, including material quality, design accuracy, and functional performance. Any deviation from these standards is a red flag for manufacturing quality issues.

Design and Appearance

This process includes assessing color accuracy, pattern alignment, and dimensional precision, along with a thorough examination of the product style, they must meet the order or client’s specification.

Labeling and Packaging

Verifying the correctness and clarity of labels, which should accurately reflect the product's characteristics, origin, and any applicable certifications. The packaging is also scrutinized for its quality, design, and protection it offers to the product, ensuring it aligns with the jewelry brand's image and standards. This inspection is crucial, as proper labeling and high-quality packaging are key to consumer trust and satisfaction.

Common Tests of jewelry inspection

-

Functionality Test

-

Capacity Test

-

Tensile Test

-

Torque Test (Twist Resistance)

-

Fatigue Test

-

Smell Test

-

Color Fastness Test

-

Rub Test

-

Wash Test

-

Drop Test

-

Barcode Scanning Test