We provide Footwear quality control services in China

Offering premier Footwear Quality Control and Inspection Services in China, we specialize in ensuring the highest standards of quality for a global clientele. With a deep understanding of both local manufacturing practices and international quality requirements, our team of experienced inspectors is dedicated to meticulously assessing every aspect of footwear production. From material quality to final product, we provide comprehensive checks to guarantee that each shipment meets your expectations.

The key points of Footwear inspection

Footwear products should be aesthetically pleasing, comfortable, and durable, which requires high-quality materials, these should include longevity, breathability, and the softness of the fabric and leather. The workmanship of stitching and gluing also demands durability, without any obvious visual defects. Additionally, the final product's size must be crafted according to the design and shoe lasts to ensure a proper fit on the foot. NBN's quality inspection services ensure that footwear meets consumer expectations and industry regulations.

Appearance and style

Inspectors need to verify the style of the shoes against the approved sample or the product specification sheet. This includes a detailed examination of the structure of the shoe, such as the height and shape of the heel, the design of the upper (including stitching, perforations, seams, etc.), the shape of the toe, and the pattern of the sole. The focus is on ensuring that the design details of the shoe match the predetermined specifications, for example, whether the laces, eyelets, and decorative items are correctly placed and installed as per the design.

Inspectors must also ensure that the overall structure and proportions of the shoe comply with the design requirements, making sure there are no missing or incorrect design elements.

Additionally, inspectors need to ensure that the color of the shoes matches the color specified by the customer or in the product specifications. This includes comparing the main color and any secondary colors. Standard color charts or provided samples should be used for comparison to ensure color consistency. Besides the basic color match, attention should be paid to the uniformity of the color, checking for any fading, uneven dyeing, or color differences.

Material

Inspectors need to confirm that the types of materials used in the shoes are correct according to product specifications or customer requirements. This includes checking the materials of the upper (such as leather, fabric, synthetic materials, etc.), the sole materials (such as rubber, plastic, synthetic composites, etc.), and the materials of the lining and insole.

For each type of material, inspectors should check whether the texture, thickness, elasticity, and durability meet the standard requirements. For example, for leather materials, it's important to examine the gloss, color uniformity, and any flaws, such as scratches or scars.

Workmanship

Sampling

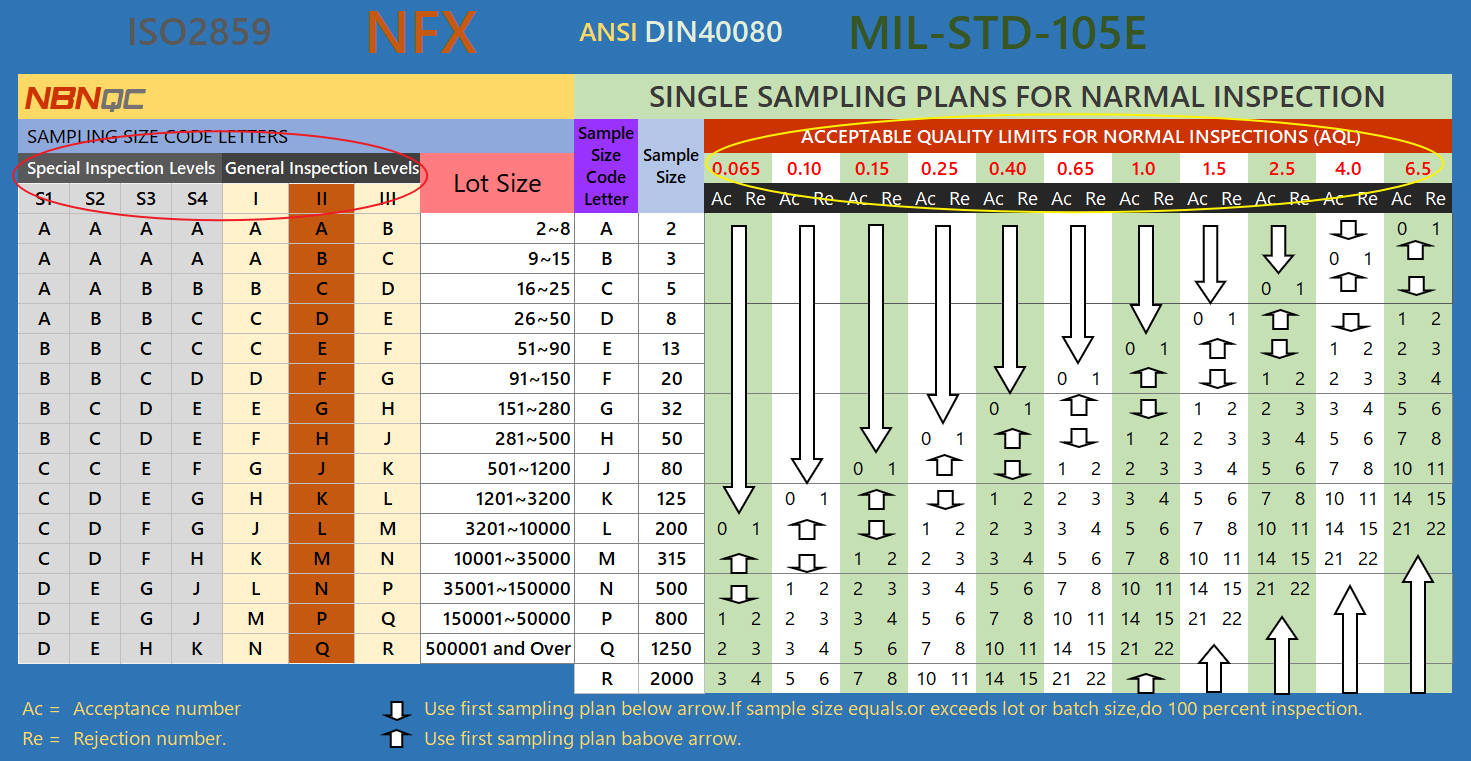

The number of samples for random inspection is determined based on the INSPECTION LEVELS requested by the client and the LOT SIZE of the goods. Then, find the corresponding AQL on the table. For example, if the required INSPECTION LEVEL is II, AQL is 0/2.5/4.0, and the LOT SIZE is 5000 pcs, then 200 pcs will be randomly sampled. The acceptable range for the number of defects is Critical 0 pcs/Major 10 pcs/ Minor 14 pcs. If the number of defects exceeds these limits, the goods will be rejected.

(Default: Inspection level II, AQL 0/2.5/4.0)

Quality check

Each sample selected for random inspection is individually examined, and all defective products are identified and segregated. These defective products are then categorized and quantified. This result determines whether the entire batch of goods falls within the AQL (Acceptance Quality Limit) range and is the key basis for deciding whether to accept or reject the shipment.

Classification of defects in garments

Critical

Discover scissors or needles, mold, insects or insect eggs, as well as other items that pose a threat to user safety, environmental safety, or do not comply with legal regulations.

Major

Fabric color variation, noticeable misalignment or twist, holes, fabric or accessory damage, and other appearance defects affecting sales.

Minor

Untrimmed thread, small spots or stains, or other defects inconspicuously that have less effect on appearance.

Footwear defect classification examples

Size Measurement

Length measurement is typically taken from the tip of the toe to the longest part of the heel, width measurement focuses on the broadest lateral dimension of the shoe, and height measurement may involve the vertical height of the heel or the shoe collar. These measurements need to be compared with product specifications or size standards to ensure that each pair of shoes conforms to the predetermined production standards. In some cases, inspectors might also need to check the size of the shoe last, as well as the internal space of the shoe or the size of the insole, to ensure overall comfort and functionality.

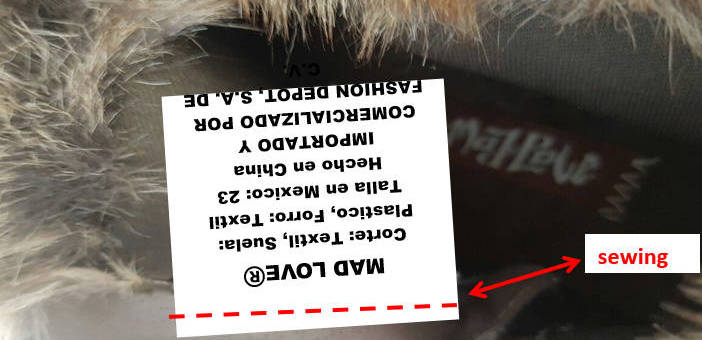

Label & Logo

The steps for verifying labels and logos during the inspection of footwear products mainly involve ensuring their position, size, color, and design are consistent with product specifications or customer requirements. Inspectors need to carefully check that the labels and logos are correctly placed in the predetermined locations on the shoes, such as the tongue, side, heel, or sole, and that their size and color match the design requirements.

Additionally, inspectors must verify the quality of printing or embossing of the labels and logos, ensuring there are no issues of blurring, misalignment, or fading, as well as checking the accuracy of text, patterns, and brand identifiers, ensuring they are clear, legible, and correct. This process is crucial for maintaining brand consistency and consumer recognition.

Packing & Packaging

Inspectors check packing and packaging by ensuring the quality, size, and integrity of packaging materials, and verifying that packaging design adheres to brand and safety standards. This includes examining the sturdiness and condition of external packaging (like boxes or bags) to protect shoes during transit, and confirming that labels, barcodes, and warning labels on the packaging are accurate and clear.

Common Tests of Footwear Inspection

-

Carton assortment check

-

Wear test

-

Pull test

-

Symmetry check

-

Bend or flex test

-

Color shading check

-

Color fastness test

-

Smell check

-

Barcode scan test