We provide Textiles quality control services in China

As a provider of textile inspection services, we focus on offering comprehensive textile inspection solutions in China for our clients. By closely communicating with customers to understand their specific needs, we develop and implement inspection processes that adhere to international standards. Our professional team conducts thorough quality checks on-site at suppliers, encompassing evaluations of raw materials, production processes, and finished products. After completing the inspection, we provide detailed reports and improvement recommendations, ensuring that the textiles meet our clients' quality requirements and relevant regulatory standards, thereby paving the way for their success in the global market.

The key points of Textiles & Fabrics inspection

It will include assessing the quality of raw materials, checking the structure and strength of the fabric, verifying dimensional accuracy, inspecting color fastness and dyeing quality, examining surface and appearance, testing physical and chemical properties (like durability and absence of harmful chemicals), ensuring the correctness of labeling and packaging, and confirming compliance with regulatory and safety standards of the target market. These comprehensive checks ensure that the textiles meet high standards in terms of quality, safety, and market adaptability.

Appearance and style

Compare samples or finished products with the design specifications or approved samples provided by the client. This includes checking whether the fabric's pattern, color, texture, and overall design layout match the specified style. Inspectors carefully compare the accuracy of the colors and the details of the patterns to ensure there are no deviations. Additionally, the proportions must be confirmed to meet design requirements. This is usually done under sufficient natural light or standardized lighting conditions to ensure accurate assessment of appearance and style.

Material

By touching the textile, inspectors can perceive its texture, thickness, and softness, which allows them to preliminarily assess whether the material type and quality meet the specifications. This step largely relies on the inspector's experience and professional knowledge.

Additionally, a circular piece of material with a diameter of 10cm is cut and weighed on a high-precision electronic scale to ensure the textile's grammage meets the order requirements. Also, inspectors request a fabric test report from the supplier to further verify its chemical composition, thereby ensuring the correct fabric is used.

Workmanship

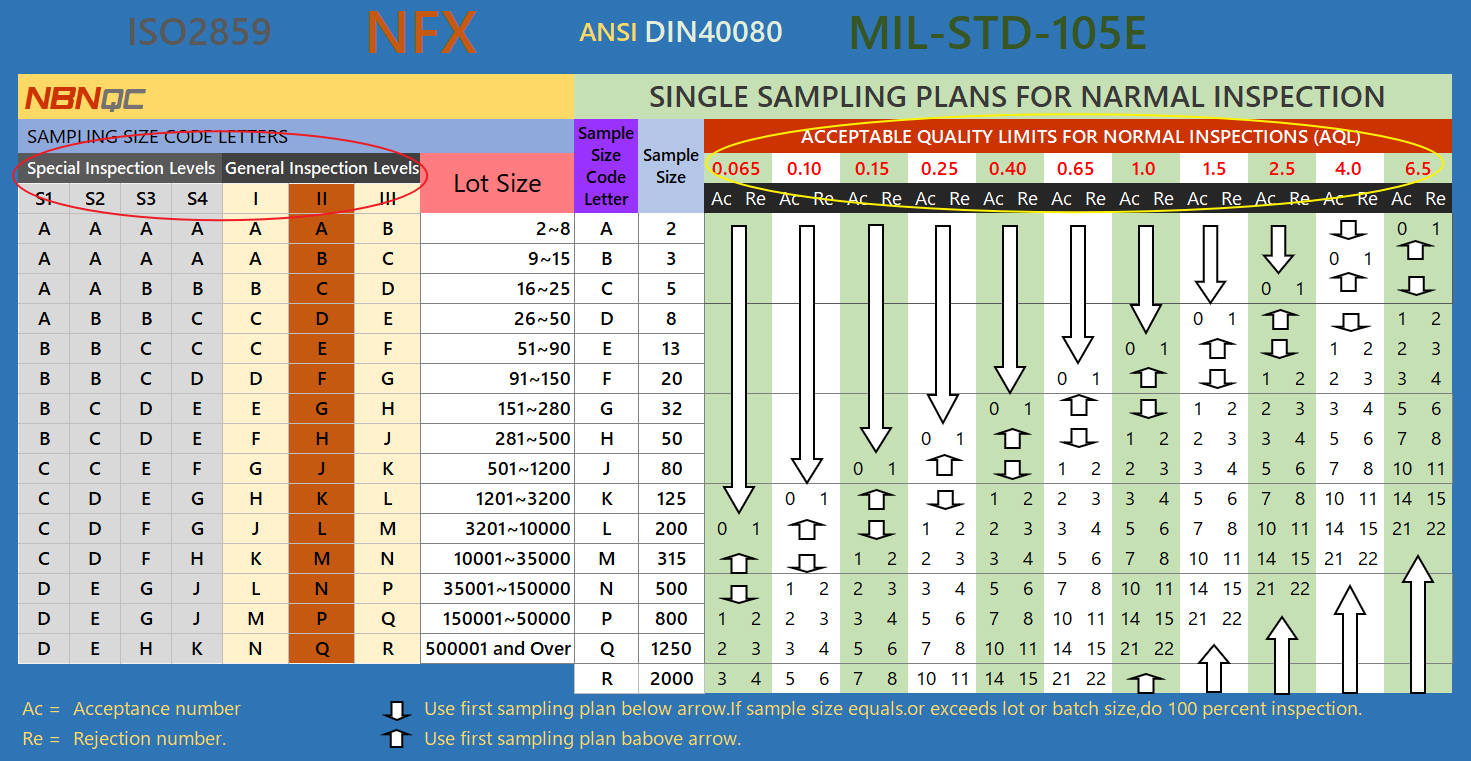

Sampling

The number of samples for random inspection is determined based on the INSPECTION LEVELS requested by the client and the LOT SIZE of the goods. Then, find the corresponding AQL on the table. For example, if the required INSPECTION LEVEL is II, AQL is 0/2.5/4.0, and the LOT SIZE is 5000 pcs, then 200 pcs will be randomly sampled. The acceptable range for the number of defects is Critical 0 pcs/Major 10 pcs/ Minor 14 pcs. If the number of defects exceeds these limits, the goods will be rejected.

(Default: Inspection level II, AQL 0/2.5/4.0)

Quality check

Each sample selected for random inspection is individually examined, and all defective products are identified and segregated. These defective products are then categorized and quantified. This result determines whether the entire batch of goods falls within the AQL (Acceptance Quality Limit) range and is the key basis for deciding whether to accept or reject the shipment.

Classification of defects in Textiles

Critical

Discover scissors or needles, mold, insects or insect eggs, as well as other items that pose a threat to user safety, environmental safety, or do not comply with legal regulations.

Major

Fabric color variation, noticeable misalignment or twist, holes, fabric or accessory damage, and other appearance defects affecting sales.

Minor

Untrimmed thread, small spots or stains, or other defects inconspicuously that have less effect on appearance.

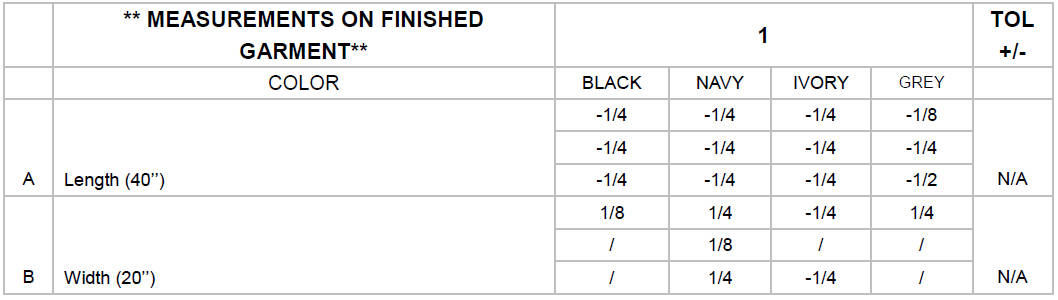

Size Measurement

The measurement charts are typically provided by the client, and inspectors perform measurements based on the chart and the quantity of samples specified in the requirements. During this process, if there are updates to the measurement chart that result in discrepancies with the supplier's chart, we will promptly confirm this with the client.

Label & Logo

In a Textiles order, there may be multiple colors and sizes, and the labels on product of different sizes and colors are also different. For example, there will be various sizes and barcodes on hang tags and care labels. During the inspection process, we will carefully verify each type of label and document it with photographs.

Packing & Packaging

According to the client's specifications, we will verify the shipping mark, outer box quality, packing method, printing on inner packaging, check for punctures in PVC bags, and the presence of desiccants, among other things.

Common Tests of Textiles & Fabrics inspection

-

Carton assortment check

-

Needle Damage & Seam strength check

-

Symmetry check

-

Color shading check

-

Sticker test

-

Stretch test (for elastic and knitted fabric)

-

Fatigue test for Velcro/Snap/Zipper/Eyelet

-

Adhesive test

-

Rub test

-

Per inch stitches check

-

Barcode scan test